A team mistakenly marked 'electroplating necessary' on a drawing,and the vendor applied decorative chrome plating,even though the actual part required a zinc-nickel alloy coating known as'metal plating'to offer rust-resistance in heavy-duty use.The part subsequently rusted seriously in a wet out-of-doors installation,incurring not only additional component replacement but other losses due to downtime.

This is not an unusual occurrence.Its source is a basic misunderstanding:electroplating≠metal plating.Although in everyday use the two processes are used synonymously,in engineering they represent different technical processes and results.

This article will contrast the basic differences between electroplating and metal plating,including basic differences,material selection,and process integration.Based on practical experience from JS,it will guide you on how to select the correct solution of surface treatment for your project.

Summary Of Basic Answer

| Comparative Dimensions | Electroplating | Metal Plating |

| Conceptual Relationship | Metal plating is a broad category of processes,a significant subset of which includes metallic and non-metallic coatings. | Electroplating is a subclass of the term that is used only for those processes depositing metallic coatings. |

| Core Purpose | To impart specialized functions such as insulation and resistance to high heat,in addition to enhancing inherent substrate properties such as wear resistance and corrosion resistance. | Emphasis is placed on enhancing inherent substrate properties such as wear resistance,corrosion resistance,and appearance. |

| Substrate | Non-metal(e.g.,plastics and ceramics)and metal substrates are acceptable. | Metal substrates are preferred since non-metallic substrates are not used commonly and require advanced processing. |

| Key Pretreatment | Non-metal substrates require activation and sensitization,metal substrates require degreasing and rust removal,so pretreatment processes are more complex. | Pretreatment is primarily degreasing,rust removal,and roughening(e.g.,sandblasting)with relatively simple steps. |

| Typical Applications | Insulated electronic component housings,high-temperature-resistant ceramic components,precision metal components. | Automotive components(galvanizing),bathroom fixtures(chrome plating),and electronic components(nickel plating). |

Why Can You Rely On This Guide?JS Surface Finishing Practices

Whether you are struggling with electroplating vs. metal plating decisions for high-temperature aerospace parts,or worrying about surface finish for medical device parts with strict biocompatibility requirements,JS has already overcome similar challenges for hundreds of customers.

With over ten years of surface finishing experience,we have gained huge technical expertise in a wide range of industries.We have been able to provide tailor-made surface finishing services to automotive precise parts,consumer electronic enclosures,and machinery parts.

Our professionals are seasoned in the finesse of combining multiple processes with materials like aluminum,stainless steel,and 3D printing plastic,and their expertise is backed by analogous project cases.

This guide is not simply a pile of theoretical knowledge, but a summary of practical experience extracted from hundreds of successful cases, which can provide practical references for practical projects.

Confused about aerospace or medical part surface finishing?JS Precision Manufacturing offers online surface finishing.Tell us what you want,and we'll provide you with a real-life solution to help you in a most effective way in getting your issues resolved.

Examining The Origin:Is Electroplating And Metal Plating The Same?

How the Two Are Related

In industrial production,the majority of people confuse electroplating and metal plating,but in reality, the two have a clear subordinate relationship.

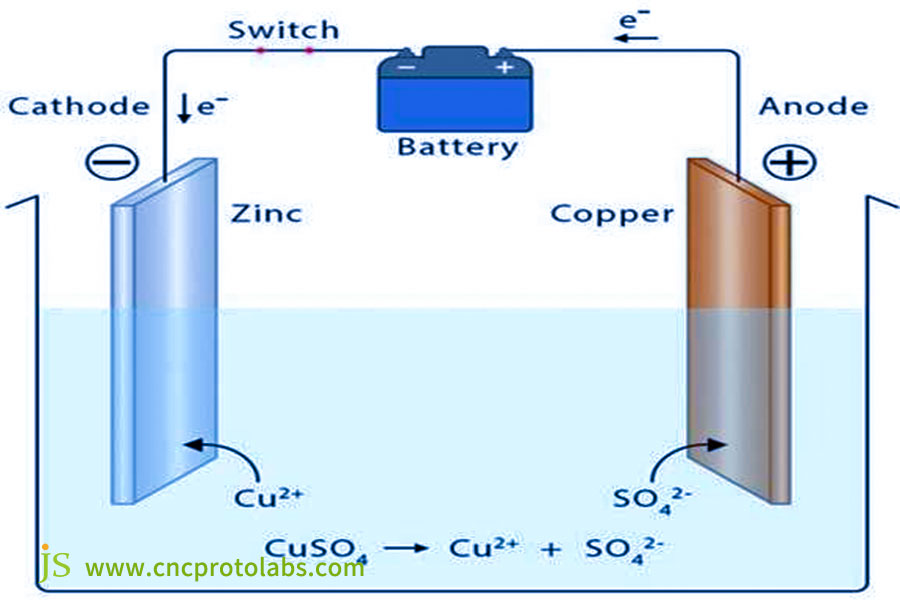

Electroplating is more extensive in its application.Besides laying down a metal coating,it lays down non-metallic coatings on plastics,ceramics,etc.,for such requirements as insulation and heat resistance.Metal plating is more specific,specially depositing metallic coatings.

Core Purpose Differences

Electroplating is carried out on metal and non-metal substrates for fulfilling specific requirements such as insulation and heat resistance.The most common application of metal plating is to protect the substrate against wear,corrosion,and improve appearance and is common in the majority of household applications and industrial components.

Surface Treatment Price Differences

In general,electroplating is more expensive than metal plating due to extensive use and complication of processes in some instances.This depends on substrate type,coating thickness,and batch size,however. For example,non-metallic substrate electroplating requires extra pre-treatment and costs 10%-30% more than metallic substrate metal plating.

Material Selection:Diverse Aims,Diverse Metals

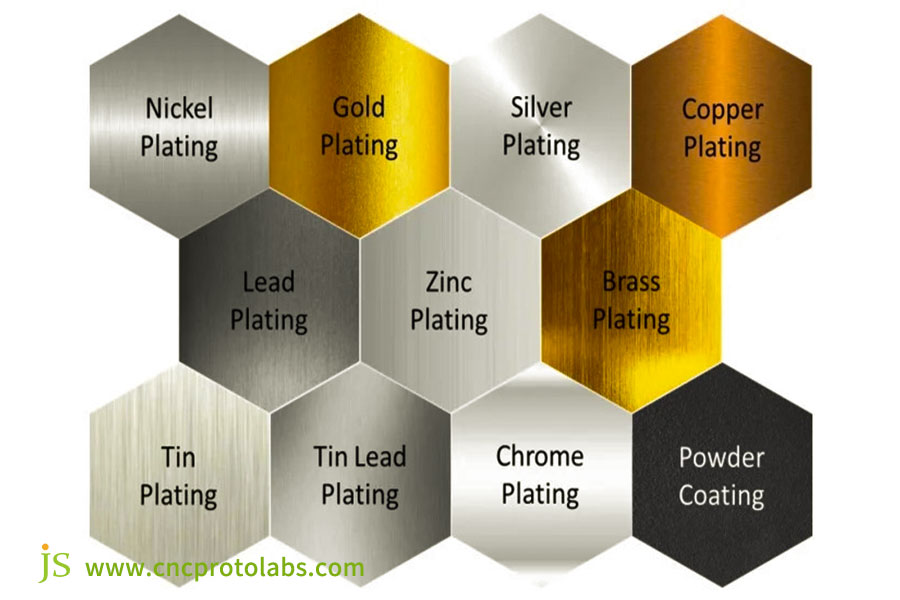

Typical Metal Plating Materials and Comparisons

During metal plating,material selection enables or disables achievement of the intended goal and impacts the surface finishing price as well.Details are laid out in the table below:

| Metal Plating Material | Function | Estimated Surface Treatment Price Range(per square inch) |

| Galvanizing | Improves corrosion resistance,can be applied on car components and building hardware. | $0.5-1.5 |

| Chromium Plating | Enhances wear resistance and appearance,can be applied on furniture fittings and bathroom accessories. | $1.2-3 |

| Nickel Plating | Increases hardness and conductivity,best suited for mechanical components and electronic devices. | $0.8-2.2 |

| Gold Plating | Increases conductivity and resistance to oxidation,best suited for jewelry and precision devices. | $5-15 |

| Silver Plating | Increases reflectivity and conductivity,best suited for optical and communication devices. | $2.5-8 |

Electroplating Material Selection Characteristics

Electroplating is more versatile with material options.In addition to the above-mentioned metals,other non-metallic parts can be used.

For example,electronic component housings with unique insulation needs can be made from plastics such as ABS and PC.The cost of surface treatment is $0.3 to $1 per square inch depending on the plastic material and process complexity.

Versatile as far as what metal plating material to choose?JS offers a wide variety of metal options with clear surface treatment prices.Simply give us your functional specifications,we'll suggest materials,and as you place an order,receive top-notch custom surface finishing manufacturing.

Coordination:How To Coordinate With Different Processing Methods?

Machining Technique Comparison and Surface Treatment

Both electroplating and metal plating require coordination with other machining processes to result in qualified surface-finished parts.Coordination points are enumerated below:

| Machining Process | Core Requirements | Surface Treatment Cost Impact | Applicable Scenarios |

| CNC Machining | Machining second,followed by treatment,full pretreatment and impurity elimination required. | Pretreatment cost accounts for 10%-20%,the higher percentage being the more complicated the part. | Mass production of customary metal/non-metal parts. |

| 3D Printing | Invades the selection of materials that are compatible with each other(like ABS or treated PLA),pretreatment is harder. | 15%-30% more expensive than CNC machining because the polishing time is longer. | Intricate shapes and small runs of customized pieces. |

Coordination with Traditional Machining(CNC)

CNC machining precisely trims the substrate.Combined with electroplating or metal plating,it is a 'CNC machining first and then surface treatment' process:machining the semifinished product→ cleaning and degreasing.Treatment failure can be caused by surface contamination,and CNC precision has a direct bearing on the outcome of treatment as well.

Integration with 3D Printing

3D printing is applicable to personalized manufacturing,but needs to take note of material compatibility.Incompatible materials will cause loss of coating.The integration process is:3D printing prototype→grinding and polishing→cleaning and degreasing→surface treatment.

Due to the difficulty in pre-treatment,the cost is greater than that of CNC integration,and therefore can be utilized to manufacture complex components.

Parameters That Make Or Break:Key Considerations For Both Processing Processes

Substrate Surface Pretreatment

Substrate surface cleanliness is the foundation of coating quality.Thoroughly remove oil,rust,and oxide layers prior to treatment.Otherwise, it will reduce the adhesion of the coating and affect uniformity. Chemical cleaning and physical grinding are popular.Pre-treatment errors can contribute indirectly to the expense of surface treatment.

Control of Coating Thickness

Coating thickness is one of the most critical quality specifications for surface finishing products,and each end use requires different specifications.A coating that is too thin compromises performance,and one that is too thick adds cost and defects.Professional equipment is required for real-time monitoring and adjustment.

Stable Process Parameters

Electroplating and metal plating have process parameters like current density,temperature,pH,and processing time.Instability will result in rough coatings,pinholes,and discoloration.Enterprises need to equip advanced control systems, regularly maintain equipment, and provide professional training for operators, otherwise it will result in non-conforming products and increase rework costs.

Worried about metal plating/electroplating concerns?JS Precision Manufacturing maintains control over all areas of surface finishing at a low price.As soon as you send us your project,we will totally guarantee a completed item and avert rework and scrap.

Green Choice:What Poses The Lowest Ecological Threat?

Ecological Threats of Electroplating

Electroplating produces heavy metal and cyanide wastewater,acid mist,alkaline mist,and metallic waste.They also pollute the environment if not properly treated.Companies will be forced to invest medium-level wastewater treatment units at $500,000 to $1,000,000 and maintenance at $100,000 to $200,000 annually.The cost may be reflected in the surface treatment price.

Environmental Hazards of Metal Plating

Metal plating poses less environmental risk,generating less wastewater containing metal ions and metal wastes which are easier to treat.The capital investment for equipment for the treatment of medium-level wastewater ranges from $300,000 to $600,000,and yearly maintenance costs range from $50,000 to $150,000,lower than electroplating.

Process Selection Recommendations

In the financial and environmental aspect,metal plating is good but electroplating can minimize risk with green technology.The businesses have to consider environmental demands,environmental spending,and surface treatment as a cost in deciding.

Prioritize environmental protection but compromise on cost?JS Precision Manufacturing offers low-risk metal plating and green electroplating.We disclose our surface treatment cost.Just state your environmental demands and we'll offer a green alternative.

Case Study:From 'Rust' To 'Immortality'—Restoration Of a Marine Sensor Housing

Client Background and Problem

A marine sensor aluminum alloy housing utilized by a technology company was initially surface treated with regular anodizing at a cost of $12 per unit.After six months,pitting and rust occurred,by which time the equipment had been installed offshore.Seawater ingress ruined the delicate internal circuitry, resulting in equipment downtime and complaints.

Failure Analysis: Further chloride ions from the sea penetrate the anodic oxide film(15-20μm thick with very small pores)and react with the aluminum alloy.Prolonged immersion and tidal activities render the oxide film ineffective,and corrosion failure results.

JS's Solution

- Solution Selection:

JS finally settled on using the metal plating group's arc-sprayed zinc-aluminum coating solution.This solution,having a coating thickness of 100μm and a zinc-aluminum ratio of 85:15,indeed shields the substrate through the sacrificial anode effect.The surface treatment was $15.6 per unit,only 30%greater than the original anodizing solution.

- Process synergy:

After CNC machining, the shell is first roughened by sandblasting, followed immediately by arc spraying (to avoid secondary oxidation of the substrate), and finally sealed with a special silane sealant to form a complete protective system for coating pores.

Results

The enclosure,independently tested by an outside laboratory,withstood a 3,000-hour neutral salt spray test(well in excess of the industry standard of 1,000 hours)with no peeling of finishes or corrosion.

Customers report that the gear has been operating reliably in the East China Sea for 18 months,with the enclosure still in like-new condition.The whole service life is expected to be extended from the original 1-2 years to more than 15 years.

Even though the cost of surface treatment per unit increased by $3.6,it avoids future cost of circuit repair and equipment replacement,improving the total value more than 10 times and eradicating the whole corrosion problem in saltwater environments.

Mari parts having corrosion issues?JS offers mature metal plating capabilities and competitive surface finishing prices.Submit your part issue and we'll duplicate your winning condition to assist in wiping out your corrosion problem.

How Do You Choose The Best Surface Treatment Process For Your Project?

The choice of the right surface treatment process is critical for project success.Not only does it impact product performance, appearance, and life,but it also directly impacts the cost of surface treatment.The following are significant steps in this choice process:

Identify the Substrate

Substrate type determines the process suitability and surface finishing price.Electroplating or metal plating can be used as metal substrates.Non-metallic substrates require special pre-treatment for electroplating,and the surface treatment cost is 20%-40% higher than metal substrates.

Define requirements

Functional specifications and appearance specifications influence process selection directly.Surface treatment prices vary significantly depending upon the process.For example,gold plating is considerably more expensive than zinc plating,and matte finishes can increase surface finishing price by 10%-15%.

Design Optimization

In design,avoid complex shapes such as deep holes and slots.Leave shield areas for areas not requiring treatment.Otherwise,the process becomes more complex and the surface finishing price increases. Equipment usage and fixture cost also impact part shape and size,further impacting surface finishing prices.

Choose a Partner

Choosing a reliable supplier ensures quality and efficiency,along with offering reasonable surface finishing prices.

JS provides better equipment and professional personnel to provide quality surface finishing parts.Our betteronline surface finishing services provide current information on the progress of your project,transparent quotations with no hidden charges,and customized solutions according to your needs.We also believe in the environment and employ green processes to ensure compliance.

Choosing JS precision manufacturing can maximize the cost-effectiveness of the project.

FAQs

Q1:Why is aluminum hard to electroplate?

Aluminum is a reactive metal.It develops an oxide coating on the surface extremely fast in the presence of air,directly preventing effective adhesion between the electroplated film and aluminum substrate.Therefore,aluminum electroplating requires advanced and stringent pre-treatment processes such as zinc immersion and anodizing to allow smoothened and high-quality subsequent electroplating.

Q2:Which provides the best rust prevention?

Direct comparison of rust prevention performance is not typically possible,as it varies with the type of coating.For example,of the typical coatings,zinc plating forms a heavy protective coating on the metal surface and provides excellent rust protection.Decorative chrome plating,primarily for enhancing appearance and wear resistance,provides less rust protection.

Q3:Why do plastics peel or flake off after prolonged electroplating?

The root cause of peeling or flakes in plastic electroplating is a breakdown in adhesion between the plating and the plastic substrate.It may be due to improper selection of plastic material,poor pre-etching,or internal stress or sharp corners of product design.

Q4:I am producing a small batch.Can electroplating be conducted?

Electroplating is also possible for small lots.JS's online manufacturing platform offers rack plating services for small lots.Simply provide the parts,and the platform will rack mount the same parts along with the same products to be manufactured.This production method can avoid the high cost of individual production, thereby significantly reducing the processing cost of small batch orders.

Summary

Understanding the difference between electroplating and metal plating is the foundation of transition from 'manufacturing' to 'smart manufacturing'.Choosing the optimal surface treatment solution requires careful examination of materials,management of the process,process details,environmental risks,and the cost of surface treatment.

In case you are doubtful about surface treatment solutions,contact JS.We offer professional custom surface finishing production and finished surface finishing parts.Simply upload a sample request or 3D part drawing and receive a detailed analysis report along with material recommendations,process alternatives,and real-time quotations.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com