Online CNC machining is more than just a service, it is a collaboration model that enables precise manufacturing at your fingertips.

Think of a scenario where you are a California engineer who requires a customized CNC machining part that needs a prototype launch in three weeks. The cost from the local CNC machining suppliers has been exorbitant with a turnaround time of up to a month.

It is exactly this gap that online CNC machining seeks to bridge.

This article will examine exactly how online CNC machining services today help alleviate these key pain points from design to delivery through online technologies, and explore just how a company like JS Precision, a leading Chinese supplier, can provide a one-stop solution from online, instant CNC machining price quotes to fast global shipping.

Central Answer Table: Comparison of Internet-Based CNC Machining with Traditional Schemes

| Customer Core Pain Points | Traditional Machining Limitations | JS Precision Online CNC Machining Solution |

| Slow and Opaque Pricing | Constant emailing/phonin, involving several days, price structuring ambigious. | Online Instant Pricing System: You can upload your drawings and obtain the CNC machining price in detail in just minutes. |

| Uncontrollable Quality and Difficult Communication | Overdependence on personal experiences, late quality inspection reports, low remote communications efficiency. | Digital Quality Closed Loop: Having complete traceability and real-time distribution of the reports (like FAIR and CMM reports) ensures complete fulfillment of requirements for every CNC machining part. |

| Delayed Delivery and Rigid Supply Chain | unclear production progress, slow reaction to unexpected events, and strong geographical constraints. | Worldwide Agile Supply Chain: Online progress tracking in real time and China’s manufacturing center guarantee sound production capacity and logistics for the rapid delivery of CNC machining online services. |

Key Takeaways:

- Selecting online CNC machining involves adopting a digital and transparent partnership process, utilizing worldwide manufacturing resources.

- Early DFM (Design for Manufacturing) optimization was the most critical step in controlling CNC machining price and improving part manufacturability.

- The top CNC machining Chinese suppliers have world-class competitiveness in terms of technology, cost, and supply chain responsiveness.

- Quality assurance relies on systematic process flow and inspection standards, rather than physical distance.

- Treating manufacturers as development partners and collaborating early can significantly improve project success rates.

Efficient And Worry-Free: JS Precision Online CNC Machining Services Guide

Our organization, JS Precision, has more than 15 years of experience in providing CNC machining services in the fields of aerospace, medical, auto, and consumer products. All the products that we manufacture are in compliance with the quality management system, including ISO 13485 and AS9100.

Until now, we have finished over 20,000 projects, from 0.5mm precision medical components to large-scale mechanical components with high accuracy. For instance, we have finished machining a titanium alloy component with a tolerance requirement of ±0.01mm for an aviation client in just 3 days from quotation to delivery, shortening their originally expected lead time by 40%.

Our team is experienced in turning complex materials like TC4 titanium alloy and Inconel alloy and has maintained an overall 99.7% on-time delivery performance for urgent orders as well.

This guidebook is drawn directly from our experience—it is the essence of the tactics and techniques we utilize working with clients, and the success it has brought to countless clients seeking quality parts efficiently. Whether it be a start-up firm testing prototypes or a company within the top 500, you can rely on these proven keys.

Are you looking to enjoy hassle-free online CNC machining services that conform to international standards? Just send JS Precision the 3D model of your part and we will give you a free DFM and quotation within 24 hours to kick-start your project quickly.

Design For Manufacture: What Are The Essential Guidelines For Your CNC Machining Part?

The key to quality manufacturing is quality design. Learning the basics and understanding the fundamental principles of DFM can greatly enhance the manufacturability of CNC machining parts. The success of CNC machining is greatly dependent on the correlation between design and the capability to manufacture. Here are the essential considerations to take note of.

Avoiding Excessive Cost Traps: Balancing Geometric Complexity and Tolerances

- Reduce Geometry: Avoid complex geometry like deep cavities, micro holes, and thin walls if possible because those features require special machining tools and result in longer machining time, thereby increasing the CNC machining price.

- Rationalize tolerance requirements: Require high tolerances only for critical mating surfaces. Each step up in tolerance grade means more process and inspection costs, so it is advisable not to over-tolerance the tolerance values.

Designed for "Efficient Clamping"

- Reserved fixture space: In components, adequate spaces for clamping or process bosses must be reserved so that the workpieces, when machined, do not remain unstable, which leads to mistakes and additional costs for reconstructions.

- Unified datum: Strive to align the design standards with the process standards as much as possible to eliminate the need for multiple clamping processes. Not only is this important for machining precision, but it is also important for controlling machining cost.

| Common Design Issues | Optimization Solutions | Cost Reduction/Efficiency Improvement |

| Over-Specificating Tolerances | Specify strict tolerances on key surfaces | Lower inspection costs 20-30% |

| No reserved clamping surfaces | Add process bosses | Reduce Clamping Error Rate by 50% |

| A number of deep cavity/ultra-thin wall | Geometric simplification | Reduce machining time by up to 30% |

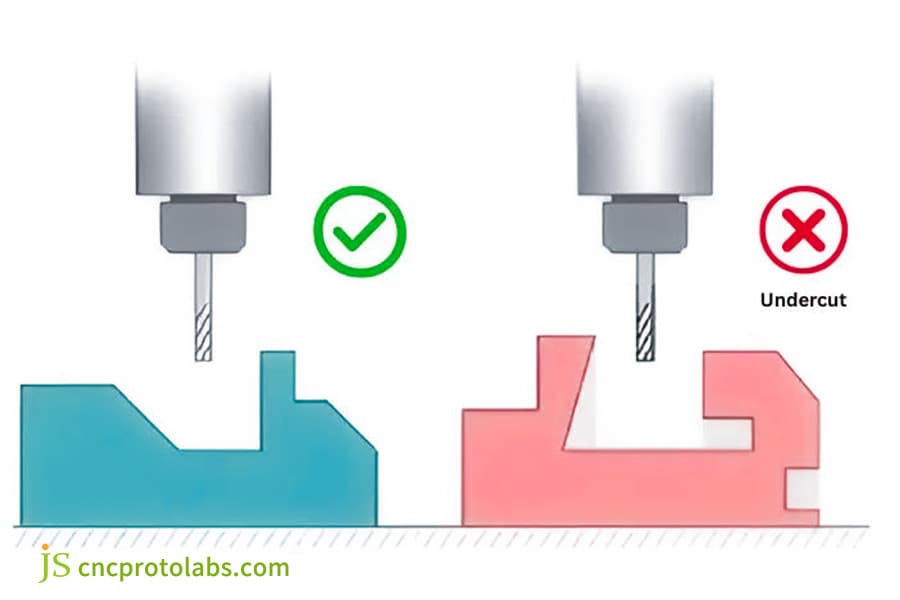

Figure 1 Minimize undercuts and deep pockets because these require special tools or multiple setups.

How Does Online CNC Machining Ensure Part Quality And Precision?

Distance is no longer a hindrance to quality assurance. Apart from that, highly advanced online CNC machining services, using digital tools, builts a more transparent quality trust system than local collaboration.

"Process approach"&based, "risk-based thinking" are defined in the International Organization for Standardization (ISO) standard ISO 9001:2015 Quality Management Systems Requirements as two fundamental principles that are essential for underpinning our own quality control system too.

Online CNC machining not only does not sacrifice quality, but also strengthens quality control through data-driven processes.

Proactive Quality Assurance: From DFM Analysis to Process Simulation

Report on Manifacturability: During the quotation phase, JS Precision engineers will conduct a comprehensive analysis of your CNC machining part, identifying potential issues such as non machinable features and material incompatibility, in order to proactively mitigate risks.

Digital Twin and Machining Simulation: Prior to actual machining, we simulate the entire path to eliminate any collision errors, ensuring no machining accidents through our digital twin technology.

Clear Process and Data-Driven Delivery

Digital First Article Inspection Report (FAIR): Once the first article is manufactured, you can expect an electronic report detailing high resolution images and full data throughout the coordinate measurement machine (CMM) analysis.

This report will highlight clearly the deviation chromatogram between the measured and theoretical data, and your critical dimensions of accuracy will be directly associated with your GD&T on the drawings.

Visualization of Key Processes: Using our project portal, you are able to view photos or videos of the machining process, participate remotely in the manufacturing process, and monitor the quality status in real time.

Want to know more about the methods used by online CNC machining providers for guaranteed quality? Request the manual on quality control procedures at JS Precision, which offers you information on how we check for the best results.

Figure 2 Accuracy and precision are crucial for successful CNC machining.

How Do CNC Machining Online Services Support Distributed Manufacturing?

With the onset of the global collaboration era, the CNC machining online service helps you to easily connect design, engineering, and manufacturing resources across the globe. The approach is dramatically changing the way manufacturing services are obtained, and it is the most appropriate approach for PDMs.

Overcoming Information Silos: Collaborative Workflows with the Cloud

- Unified Project Data Hub: 3D models, 2D drawings, technical requirements, communication records – everything is organized into a single hub where the same version of the data is accessible across the entire globe.

- Asynchronous and efficient communication: Comments, tags, and progress updates are all accomplished online and independent of the time zone, and communication trails are traceable, so the efficiency of decision-making is increased.

Leveraging the Cluster-Advantages of "Made-in-China"

- Supply Chain Depth and Resilience: China’s integrated industry chain provides easy access to raw materials, cutting tools, and spare parts, so complex projects can continue uninterruptedly.

- Scale Economies and Cost Competitiveness: The large-scale establishments of industrial clusters, in addition to advanced processes, enable major CNC machining suppliers, such as JS Precision, to provide highly cost-effective solutions while preserving quality.

Ready to use the CNC machining online service for your remote workforce? Reach out to JS Precision to set up a demo of our cloud collaboration solution to see how we can help speed up and optimize your worldwide manufacturing process.

From Click To Ship: Demystifying The Process For Your CNC Machining Online Order

Here is the standard online CNC machining service offered by JS Precision. We have ensured that every step is made as simple as possible so that online CNC machining is as convenient as online shopping.

Phase 1 - Instant Quotation and Design Optimization (Hours: 1-24)

- File Upload: Your process kicks off with a file upload. You need to submit a 3D file in STEP/IGES format and PDF plans with requirements.

- Intelligent Quotation: Based on an automatic analysis of the part’s geometry and the material and process database, you will receive an extensive CNC machining price within minutes.

- DFM Collaboration: You will be provided with optimization recommendations from senior engineers and collaborate with them to validate which manufacturing option is best.

Phase 2: Digital Production & First Article Verification (1-5 days)

- CAM Programming and Simulation: The process engineer creates and validates the machining program.

- First Article Machining and Inspection: Create the first article and perform the full dimensional inspection and submit a report for approval.

Phase 3: Mass Production & Transparent Delivery (On-Time Delivery)

- Batch production and process inspection: Promote production according to plan and conduct quality spot checks during the production process.

- Final inspection, processing, and shipping: Complete the final inspection and surface treatment, professionally package and ship, and synchronize logistics tracking information.

Right from the time you place the order until the time the order reaches you, the process will be very clear and streamlined, with a team assigned for support.

How Online CNC Machining Services Guarantee Fast Delivery?

"Fast" encompasses not just the machine's speed but also the synergy of the supply chain in general. Fast, in the context of online CNC machine services like JS Precision, boils down to how fast the delivery of the product can be accomplished while not compromising the quality of the output.

Reducing Waiting Time Through Seamless Integration as a Result of Digitalization

- Automated Processes: Right from the quoting process to the approval process, each and every process is automated, thus reducing the time spent due to manual processing.

- Prefabricated Production Preparation: Our system preparation procedures start simultaneously from the moment that you confirm your order.

Aiding and Assuring Production Time: Accurate Production Scheduling and Logistics through Data Analysis

- Real-time Capacity dashboard: Our ERP software is capable of intelligent production schedule planning, securing delivery dates, and monitoring production status.

- Mature Export Logistics System: Cooperation with top logistics companies globally provides stable and predictable transportation network solutions between doors to facilitate "last mile" deliveries.

Figure 3 Online ordering of CNC machining parts has many advantages, including instant quotes, FFM feedback, faster delivery speed, and lower costs.

How To Reduce Your CNC Machining Price Intelligently

Controlling the CNC machining price is a science that focuses on "eliminating waste" rather than lowering standards. Using scientific approaches, it is possible to cut costs and still have quality parts.

Design Side Cost Reduction Levers (affects up to 70% of Costs)

Material and Process Matching: Choose the appropriate material grade and condition to avoid excessive performance. For example, if the environment favors the project, 6061-T6 machinable material should be used in place of 7075-T6.

Optimize Feature Design: Instead of sharp corners use rounded corners, increase wall thickness appropriately, and do not make grooves too deep for milling. These changes can directly reduce processing difficulty and time, thereby reducing costs.

Creating and Collaboration-Side Cost Reduction Stratgies

Batch and Standardization: In small batch production, standardizing the dimensions of the parts can be attempted to facilitate intelligent nesting on material panels.

Supplier Selection for CNC Machining: Working with CNC machining suppliers like JS Precision, who have comprehensive processes and are proficient in optimization, often results in cost savings that far exceed unit price differences due to our engineering recommendations.

Do you want to intelligently lower your CNC machining price? Consult JS Precision's cost optimization experts, who will analyze your design and requirements, provide tailored cost reduction recommendations, and help you save expenses without sacrificing quality.

Case Study:70% Faster Delivery! How Online Collaboration Accelerated a Critical Medical Clamp To Market

Client Problem

A European and an American medical equipment enterprise required a biopsy clamp manufactured from stainless steel ASAP so that the clinical trial could be conducted promptly. A local supplier of CNC machining services offered them a delivery term of 7 days at a cnc machining price in excess of $3,000.

JS Precision Solution

The solution provided by JS Precision began with an immediate response to the website. The customer posted the designs on our website late in the evening, and they received a comprehensive quote and delivery in 4 days within 1 hour.

At the same time as the customer confirms the order, our engineers have initiated DFM optimization, indicating minor support of a hard-to-cut thin walls feature, thus enhancing cutting efficiency, and medical grade performance was to be maintained. The medical grade polishing process was also confirmed.

We also initiated the digital fast track, where the entire process, from programming to the machining and inspection, was tracked online and visually. This precise CNC machining part took only 48 hours to complete. Next, we expedited the customs and delivery, and the total processing time from the time the order was placed to the delivery was below 3 days.

Value for the Client

This collaboration enabled the client to decrease the time to project completion by more than 70% and cut manufacturing costs by over 35%, allowing them to effectively capitalize on the pivotal time frame for clinical validation and attain a competitive advantage in the marketplace.

Client Feedback: "A potential delay of up to 4 weeks became a success in only 3 days with the aid of JS Precision’s website. Not only was the part easier to machine, but the design also improved the performance. Such engineering support is priceless." - Chief R&D Engineer, a medical device company (name anonymous due to confidentiality agreement).

Do you want to accelerate project progress and reduce costs like this client? Share your CNC machining part requirements with JS Precision and obtain exclusive online collaboration solutions.

Figure 4 Stainless steel biopsy fixture

How To Evaluate And Partner With Top CNC Machining Suppliers?

Picking the CNC machining suppliers effectively amounts to choosing the integrated set of technical skills, business systems, and reputation itself. The appropriate supplier makes the online CNC machining experience successful, whereas the wrong one could mean delays, cost overruns, and quality problems.

Evaluating the Strong Points of Others - Technology and Quality Systems

- Equipment List and Process Scope: Evaluate their equipment list and scope of processes to find out if they have the ability to handle the complexity of your parts, equipment such as 5 axis cnc machining and mill-turn machines.

- Quality Control Certifications and Processes: Ascertain the presence of ISO 9001 and other quality-related certifications, and familiarize yourself with the quality evaluation process (IQC/IPQC/FQC) and precision equipment (coordinate measuring machine) they employ.

Evaluating Soft Skills: Communication and Service Culture

- Response Speed and Engineering Support: Notice how quickly they respond to the initial contact and how well they offer DFM feedback to help optimize the design.

- Transparency and Case Studies: Look into how transparent they are about their pricing structure, if they have success stories or reviews related to your business type that they can share with you, or how user-friendly their online CNC machining platform interface is.

Searching for trustworthy CNC machining suppliers? Let’s schedule a consultation together with the JS Precision team. We will demonstrate our expertise, quality, and success cases in working with clients to help you in making the right decision to partner.

FAQs

Q1: Which files do I need to attach for the best possible quote via the website?

With the ability to provide a 3D model in the format of STEP/IGES and PDF with complete tolerances, materials, and the need for surface treatment, the supplier can immediately analyze the information of the parts, thus providing the most accurate quote.

Q2: How do I safeguard my intellectual property rights for my designs when shopping online?

A legitimate online CNC machining services supplier will require you to sign a confidentiality agreement (NDA) and encrypt the data on your server to protect the security of intellectual property rights to designs.

Q3: The minimum order quantity, what is it?

Online CNC machining is most suitable for prototyping and small-batch production. The order quantities begin from just one piece. This is indeed apt for on-demand manufacturing and caters to the varied needs of different customers from sample testing to small-batch mass production.

Q4: May I contact you if I have any questions regarding the quote you have given me?

Of course. All legitimate CNC machining suppliers provide professional engineering support. You can communicate with engineers directly for quotation information, process, cost, and other related issues.

Q5: How do I check the production status of my orders?

There is an online customer portal offered by the suppliers. With the online portal, you are able to track the progress of your order, just as you would track a parcel, right from the programming and machining process, as well as the inspection and shipment process.

Q6: What are the usual tolerance ranges?

For medium-scale metal CNC machining part, a normal precision level would be ±0.025mm or ±0.05mm. If the precision level goes higher, this has to be clearly shown on the drawing plans and discussed with the supplier on the Design For Manufacturing level.

Q7: Are your testing activities done internally or contracted to a third party?

Also, good online CNC machining services vendors own comprehensive testing laboratories equipped with professional machinery such as coordinate measurement machines, projectors, and surface roughness testers to facilitate quality checks.

Q8: Why pick a supplier of CNC products from China rather than an indigenous company?

By choosing Chinese CNC machining suppliers, you can gain comparable technical capabilities and quality standards to the local market, while enjoying significant cost advantages brought by Chinese manufacturing, strong supply chain resilience, and the convenience of 7x24 hour digital collaboration.

Summary

Online CNC machining services are more than a convenient way of submitting orders for manufactured components, they represent a true revolution in the manufacture of components, with a synergy of precision, efficiency, and cost savings.

JS Precision, a leading manufacturer of precise products, has comprehensively integrated advanced engineering technology, quality control, and a user-oriented online platform. At JS Precision, we aim to ensure all CNC machining online orders become smooth and satisfying experiences for users.

Ready to transform the supply chain?

→ Upload the drawings now, you can enjoy the intelligence of the quote in 60 seconds.

→ Schedule an expert consultation to discuss your long-term manufacturing strategy.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com