5 axis CNC machining services can address numerous difficulties in machining complex parts—Conventional 3-Axis CNC machining becomes insufficient when your design involves complex surfaces, multi-angle features, or challenging integrated features.

Doing all the machining in a single setup and thus ensuring a geometrical freedom that borders on infinity—this is the revolutionary potential offered by the 5 axis CNC machining. Yet to utilize this highly advanced technology efficiently, it is necessary to confront a set of systemic challenges from programming strategies to collision avoidance and cost management.

This guide combines the experience of JS Precision in coming up with an in-depth review of the major benefits, precision logic, and design philosophy of the 5 axis CNC machining services, and reveal how to collaborate with a truly expert level supplier to turn your most ambitious designs into reliable reality.

Key Answer Summary

| Core Consideration Dimensions | Common Risks and Misconceptions | JS Precision's Professional Solutions |

| Technology Selection | Misuse of 3+2 positioning instead of linkage, or excessive use of five axes leading to cost waste. | Feature-driven process matching: Completely geometry-based, suggesting the most economical 3+2 or 5 axis linking process. |

| Precision Assurance | Believing that the precision of five axes is inevitably lower than that of three axes, or ignoring the dynamic precision and thermal stability of machine tools. | Full process precision control: from high rigidity 5 axis machining center, constant temperature workshop to on machine inspection, ensure that the dimensional and positional tolerances of 5 axis CNC parts are stable and meet the standards. |

| Design and Cost | Inappropriate designs, which do not meet the characteristics of 5 axis machining, cause programming challenges, ineffectiveness, and skyrocketing prices. | Proactive Collaboration in DFAM: Our services in the optimization of designs for additive and subtractive 5 axis machining enable cost management. |

| Project Implementation | The suppliers lack overall experience in engineering for complex parts (like 5 axis robot arm) leading to late deliveries. | Engineering Capabilities: We offer end-to-end solutions in mechatronic simulation, optimization, machining, and assembly verification. |

Key Takeaways:

- The main value of 5 axis machining is in "complex integration," as it achieves smaller clamping time, higher precision of complex surfaces, and the ability to process complex surfaces, making it the most advanced machining solution.

- Success begins with 'manufacturability design': early collaboration with suppliers for DFM analysis is key to optimizing processes, avoiding programming pitfalls, and controlling costs.

- In DFM Analysis: Precision comes from system quality, not from the number of axes. A high-precision 5 axis machining center with high stability and strict process requirements are the bases that guarantee high-precision 5 axis CNC parts.

- Partner selection = selection of experience basis. What is most important is evaluating case studies of success on comparable projects (such as 5 axis robot arm) rather than just comparing costs.

Why Choose 5-Axis? JS Precision's Practical Guide And Solutions

JS Precision has extensive experience in the 5 axis CNC Machining business for 15 years, with more than 5,000 customers in 12 key sectors: aerospace, medical, and new energy, among others.

Our work has included designing integrated landing gears for leading global drone companies, machining implants with precision as low as 0.005mm for medical device firms, and doing mass production of titanium alloy 5 axis robot arms. In one of our aerospace parts projects, we even managed to reduce weight by 35% while performing 200,000 fatigue tests without failure.

Our team has worked on over 100,000 drawings for complex parts, having addressed many challenges in various industries such as deep cavity machining, deformation problems, and collision avoidance.

This guide is not a collection of theories and opinions, but rather the summarization of experiences accumulated through thousands of successful projects, having checked every recommendation through reality.

The ISO standard, ISO 10791-1:2015 CNC milling machines and machining centers—Accuracy verification—Part 1: Geometric accuracy, is the basis of the accuracy calibration of 5 axis machines and is also one of the most important standards we follow in order to guarantee the accuracy of the machine.

Looking for a quick solution to your 5 axis CNC machining needs for complex parts? Now, share your part requirements & technical specifications with us, & we shall give you a FREE Feasibility Report & customized process plan to make complex machining easier & more reliable!

Why Choose 5 Axis CNC Machining For Complex Parts?

5 axis CNC machining is more than just integrating two rotary axes because it revolutionizes and reshapes concepts related to design freedom and manufacturing, which previously made machining complex parts inefficient.

Core Advantage 1: The Ultimate Conquest of Geometric Complexity

- Continuous Complex Surface Machining: Finish impellers and turbine parts in a single operation with no machine marks so that subsequent grinding work becomes unnecessary.

- Multi-angle feature formation: Reduces the requirement for several clamping steps as required for angled holes, bevels, and so on.

Core Advantage 2: Total Enhancement of Quality, Efficiency, and Capability

- Leap in Precision: It decreases repetitive positioning, eliminates the accumulation of errors, and provides a leap in precision of more than 30%, in contrast to the conventional method.

- Efficiency Revolution: This improves tool posture with the help of short-edged rigid tools. It enables the completion of large volumes of cutting with a reduction in the cycle time of 40-60%.

- Breakthrough the forbidden zone: easily process deep cavities and narrow seams that cannot be reached by three-axis, without the need to disassemble parts.

Precision Unveiling: What Standards Does High-Precision 5 Axis CNC Parts Follow?

The accuracy in 5 axis CNC parts manufacturing has always remained a systematic engineering procedure that entails machine tools, processes, environments, and measurements, in which any factor affects the result.

Two core systems that have been found to influence precision

- Inherent Machine Tool Precision: With dependence on the RTCP function for accurate tool paths, linear and Rotary axes have micron-level accuracy, with temperature deformation corrected for by thermal compensation.

- Process Chain Stability: Tool path smoothness influences surfaces, while corresponding cutting parameters and rational fixtures absorb vibrations.

Verifiable Precision Delivery

- Standard Certification: Strictly following ASME Y14.5 or ISO 1101 specifications, in accordance with ISO 9001/AS9100 systems, along with complete inspection reporting.

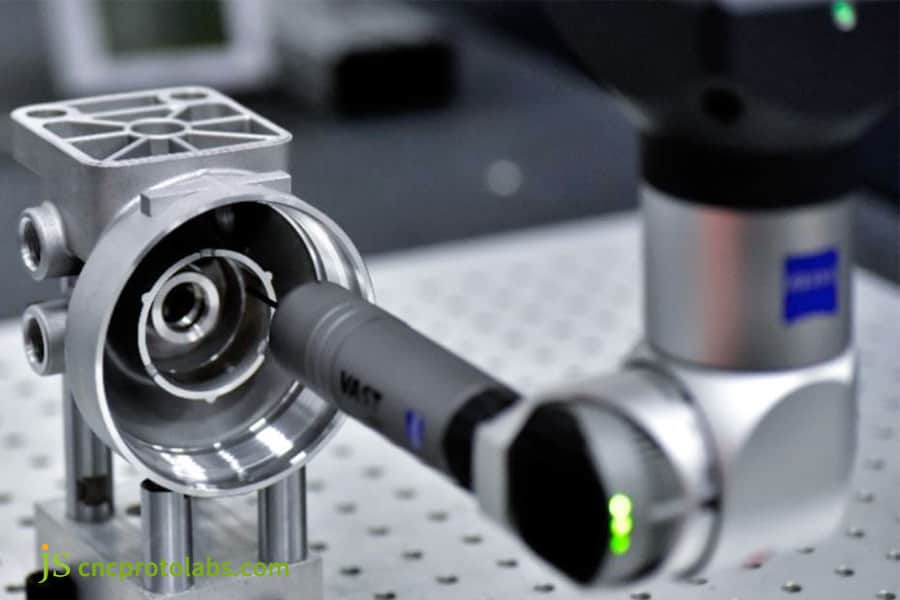

- Inspection Techniques: Using high-precision CMMs and laser trackers to verify complex dimensions in space.

Figure 1 Measuring 5 Axis CNC Machined part accuracy with Zeiss CMM.

What Challenging Materials Can Professional 5 Axis CNC Machining Services Handle?

The prime benefit of the 5 axis CNC machining services offered not only involves the machining of complex shapes but also addresses different hard-to-machine materials based on the requirements needed by the industry.

Strategies for Machining High Performance Metals and Alloys Using 5-Axes

- Aerospace Alloys: Ti-6Al-4V titanium alloy material of high strength and low thermal conductivity to reduce heat generated during cutting, high-pressure cooling and cycloidal machining.

- Mold Steel: When machining deep cavity molds like H13, the optimum tool overhang helps in achieving the sidewall accuracy and surface finish.

Machining of Non-Metals and Composite Materials

- Non-metals and composites: In the case of engineered plastics and CFRP, with a tendency to form delimiting and burrs, higher quality machining is performed with the help of specialized tools and vacuum adsorption jigs.

5 axis Machining Adaptation Strategies for Common Materials

| Concrete Materials | Machining Difficulty | Overall Strategy |

| Titanium Alloy Ti-6Al-4V | Poor thermal conductivity, strong mechanical properties | High-pressure cooling, cycloidal milling |

| Carbon Fiber Composites | Prone to delamination, burrs | Vacuum adsorption, special tools |

| Mold Steel H13 | Deep cavity machining, high rigidity requirements | Optimized tool overhang, precise speed control |

Require machining of ‘difficult-to-machine' materials? Let us know what materials you have and what you need machined, and we can tailor our solution to our ‘5 axis CNC machining services' for you to have access to AS9100D certified parts.

How To Fundamentally Avoid Collisions In Complex 5 Axis CNC Machining?

Collisions are the most prominent risk involved in 5 axis CNC machining. This can cause damage to tools and workpieces. The machine tool can even be damaged. Prevention is better than cure.

Several software-level safeguards:

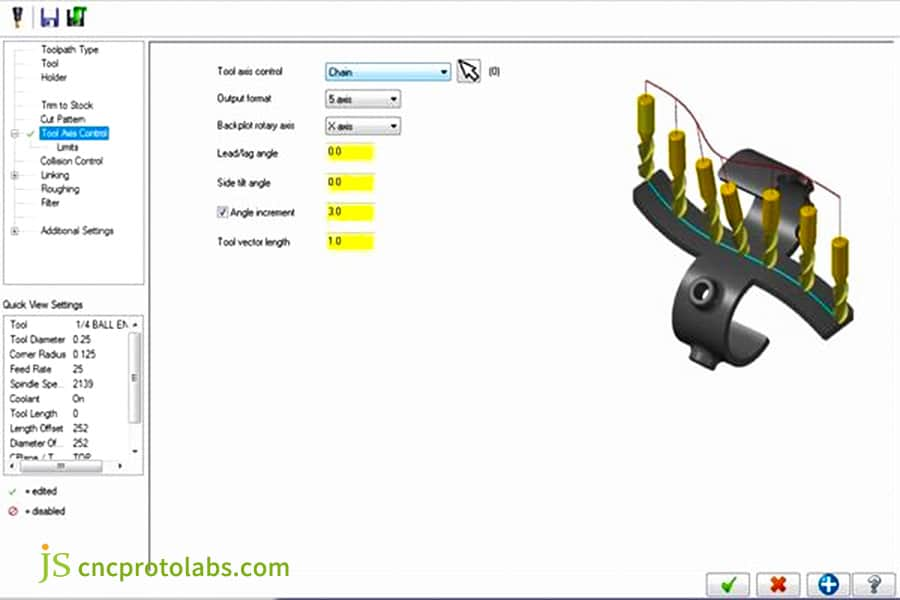

- State-of-the-art CAM simulation, utilizing Vericut software to simulate motion on a CNC mill at a level comparable to programming CNC machines, in order to analyze potential interference.

- VM tool model: Replica creation with 1:1 accuracy for the 5 axis machining center based on its structural and stroke movements.

Process and on-site management:

- Standardized clamping library: Utilizing simulated verification of standard fixtures to mitigate the possibilities of collisions with customized fixtures.

- Trial cutting procedure: The first component cut is done at slower speeds, and it is done under the supervision of senior engineers.

Figure 2 Programmers must learn to use collision control parameters, which limit the tilt angle and direction of the tool.

How To Control Budget With 5 Axis CNC Machining Services?

Enjoying the efficiency and accuracy of 5 axis CNC machining services do not necessarily come with an expensive price tag. It all depends on finding the right and most efficient solution, and not necessarily the cheapest one.

Optimizations that Involve a Decisive Choice

- DFM (Design for Manufacturability) Consultation Services: Our engineers optimize part fillet radii, draft angles, and aspect ratios, reducing areas that require extra long cutting tools or extremely inefficient machining.

- Part Integration Design: In collaboration with the integrated benefits of 5 axis CNC machining, multiple assembly parts are integrated into one unit in order to reduce assembly costs and weights.

Programming and Process Optimization

- Hybrid Process Strategy: It optimally combines 3+2 positioning machining and 5 axis simultaneous machining based on various areas of the workpiece to ensure better efficiency without affecting precision.

- Toolpath Optimization: Using high-speed milling techniques with smaller step overlaps, higher spindle speeds, and faster feed rates, which resulted in enhanced surface qualities with reduced machining times.

What Is The Essential Difference Between An Excellent 5 Axis Machining Center And a Traditional Three-Axis?

Machine tools are the basis of 5 axis machining. Specialty 5 axis machining center is much different from 3-axis machine tools with rotary attachments in terms of capability, accuracy, and rigidity.

Structural Rigidity and Drive System

- Motion Control and Drive Technology: The built-in cast iron structure is more rigid and precise compared to others that include a rotary table, while torque motors provide fast motion, high precision, and non-maintenance operation.

- CNC System: High-end CNC systems are equipped with the capability to perform 5 axis operations in conjunction with the use of circular grating, closed-loop feedback in the Heidenhain & Siemens 840D systems.

CNC System & Software Ecosystem

- High End CNC System: High-end CNC systems such as Heidenhain and Siemens 840D support native advanced 5 axis functionality, which focuses on enhanced forward control and compensation capabilities.

- Closed-Loop Feedback System: High-precision circular gratings on the rotary axes allow for accurate feedback on motion position, ensuring true closed-loop feedback system accuracy.

Interested in learning about the conditions to apply 5 axis machining center? Dial our hotline and let us know your requirements, and we will give you a free machine configuration suggestion.

Design Guide: How To Make Your Cad Model Naturally Suitable For 5 Axis CNC Parts Manufacturing?

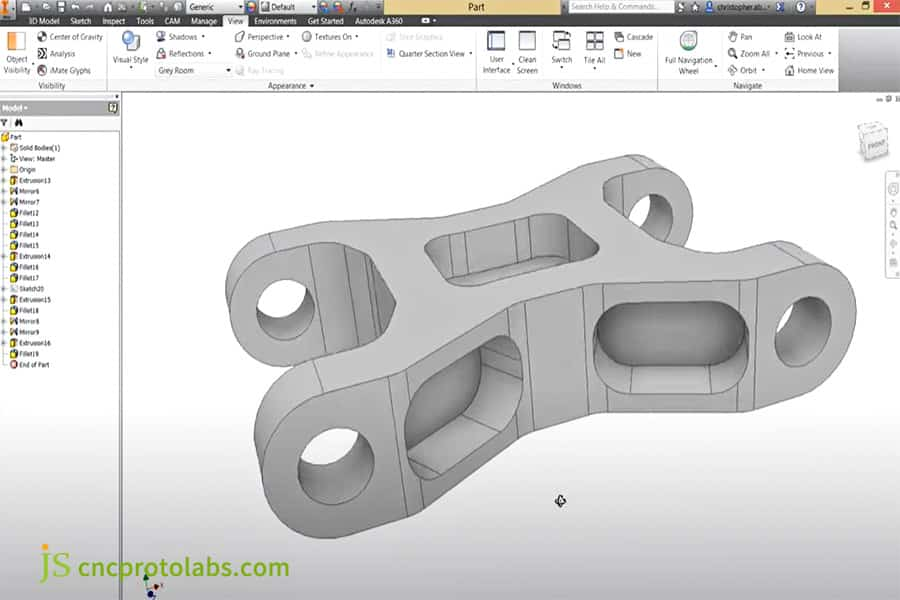

Good designers understand the intersection of functionality with the ability to manufacture, using the created CAD models in the manufacturing of 5 axis CNC parts.

Golden Rules of Geometric Design

- Do not have inaccessible sharp corners, provide fillets that are accessible to the tool.

- Think about the length-to-diameter ratio of the tooling, provide room in deep cavity designs or opt for tapered sidewalls.

- Take advantage of standard elements to minimize the usage of specialized equipment.

Manufactured for Precision & Efficiency

- Provide a means of establishing a datum system that can be easily aligned and measured.

- Optimize thin-walled rib design to prevent machining vibration or deformation.

Figure 3 For five axis CNC machining, you have greater flexibility in part modeling. Therefore, you can design more complex parts without worrying about production difficulty.

What Are The Unique Challenges Faced In Manufacturing a 5 Axis Robot Arm With High Dynamic Performance?

A 5 axis robot arm involves lightweight design, rigidity, and internal complex cavities. These can be said to constitute the very essence of complete 5 axis machining capability, as they pose rather challenging tasks in manufacturing.

Integrated Structure and Lightweight Challenges

- Integration and Lightweighting: Through topology optimization design of the biomimetic ribs, integration of weight reduction and rigidity is realized, while complex flow channels machined in one piece eliminate leakage.

- Precision and Dynamic Balance: Joint bearing holes must have geometric tolerances at the micron level, while balancing the mass of rotary parts dampens vibrations at high speeds.

Balancing Precision and Dynamic Performance

- Precision Control of Key Mating Interfaces: The geometric tolerance of joint bearing mount holes needs to be controlled in micron values, else, it will hamper the flexibility and precision of the 5 axis robot arm.

- Dynamic Balance Considerations: In rotational parts, it will be necessary to achieve equal masses, and dynamic balance optimization should be carried out while designing and manufacturing in order to prevent vibration while moving at high speeds.

Overcome the Challenges Involved in the Manufacturing of a 5 axis robot arm? We invite you for the process of discussing your requirements.

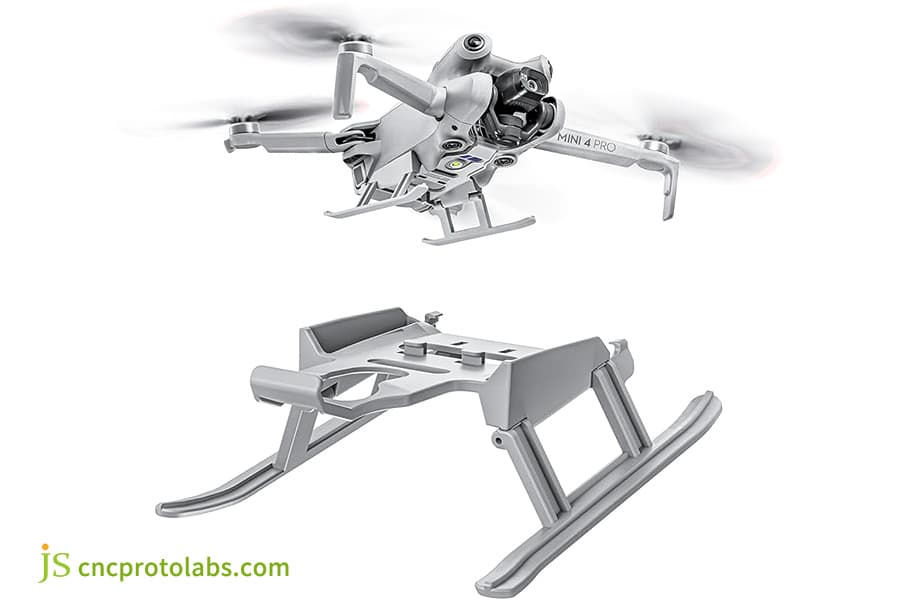

Case Study: How 5-axis Machining Can Reduce Weight By 35% And Improve Strength Of Unmanned Aerial Vehicle Landing Gear

Being one of the structural load-carrying components, it is necessary for the landing gear of the UAVs to be light with ultra-high strength. Conventional technologies cannot provide all these properties simultaneously.

The Bottleneck of the Original Design: the Performance and Cost Dilemma Caused by Multi-component Assembly

The conventional solution uses aluminum alloy welding and assembly, making it a total of 28 self-contained parts that weigh 2.1 kg.

Main Pain Points: Welds have cracking problems after landing tests in excess of 50,000 cycles. Assembling various parts results in accumulated errors in excess of ±0.3 mm, leading to problems in the functional reliability of the deployment and take-off system. It takes 4 hours to assemble a set.

JS Precision's 5 axis Integrated Solution: Design Restructuring & Precision Manufacturing

- Design Side: We will utilize topology optimization and generative design to repurpose the primary structural component and create an overall lightweight model made of titanium alloy (Ti-6Al-4V), and biomimetic ribs.

- Manufacturing End: With the utilization of 5 axis CNC machining, it is possible to mill complex surfaces, irregularly shaped mounting surfaces, and weight reduction holes in a single setup with 100% geometry conformance.

Quantitative Results: Performance Leap and Lifecycle Cost Optimization

- Integration: By combining design and machining, the number of pieces is reduced from 28 to just 1, with no assembly errors.

- Weight Reduction: The weight has been reduced to 1.37kg, resulting in a remarkable 35% decrease in weight, thereby increasing the endurance time of the

- High Reliability: Fatigue test life > 200,000 cycles, reliability > 300% improvement.

- High Efficiency: Assembly time was shortened to 0.5 hours per set, efficiency was enhanced by 85%, and the cost was greatly lowered.

Interested in realizing a performance breakthrough for your components as well? Please provide us with your product demands and pain points, and we will tailor a 5 axis CNC machining solution for you, making breakthroughs in weight reduction, efficiency enhancement, and cost cutting, so as to raise your product competitiveness.

Figure 4 Drone landing gear

Why Trust JS Precision’s 5 Axis CNC Machining Services?

The decision to employ a 5 axis CNC machining services supplier rests on their technological potential realization. JS Precision has extensive experience and reliable service support.

From Technical Equipment to Talent Think Tanks

We own a fully closed-loop high-end machine tool group, which has direct-drive and thermal correction functionality to guarantee machining stability, in addition to a team of high-level engineers dedicated to technical services involving the whole technical chain, from design to mass production.

Quality Culture and Project Assurance

We implement the digital quality closed loop with full data traceability. Our project managers also check on each complex project for smooth communication on delivery.

FAQs

Q1: What is the smallest batch size for five-axis machining, and can it be used for prototyping applications?

Prototyping can be done in 5 axis machining. Prototyping and small- to medium-series production is what we focus on, starting with single-piece production. In complex prototyping, 5 axis machining helps in completing the design in lesser time without assembling and debugging various simple components.

Q2: The surface finish that can be obtained by 5 axis machining?

With the help of rapid finishing techniques and stable performance of machine tools, the usual Ra value of surface finish quality for 5 axis machining can achieve 0.4-0.8μm, and even better quality can be ensured in certain conditions to satisfy the requirements of precision parts.

Q3: What are the maximum and minimum sizes for 5 axis parts you are capable of working with?

Our 5 axis machining capabilities range from the manufacture of millimeter-sized micro-medical bone plates to the machining of aerospace structural parts of up to 2000mm in diameter. Certain sizes have to be verified through drawings and machine capabilities.

Q4: Is there any significant cost difference or difference in turnaround time for 5 axis machining of aluminum and steel parts?

The variation is quite large. Compared with machining parts made of steel and titanium alloy materials, machining parts made of aluminum takes shorter time and is much cheaper. A concrete assessment regarding the solution will be needed taking into consideration the properties of the material.

Q5: What measures do you adopt to ensure consistency between the CAD model and the machined workpiece over complex curved surfaces?

We ensure that the level of accuracy reached during the machining process is achieved through precise CAM programming, combined with highly dynamic machine tool performance. Additionally, we adopt on-machine measurement or post-processing of coordinate scanning comparison to ensure consistency between the machined workpiece and the CAD model.

Q6: How would you handle the problem of chip removal and cooling in deep cavity components?

We employ internal cooled tools and a high-pressure cooling system, in which water is delivered through the spindle center. The tool path is also tailored in a way that encourages chip removal, thus avoiding tool breakage because of heat generation and entanglement of chips.

Q7: How can I check whether my role is suitable for 5 axis machining?

Whether the component is suitable for 5 axis machining is depending on whether it involves multiple clamping processes, whether it involves tilted features, whether it involves complex curved surfaces, or if it involves extreme light weighting. On your part, you are welcome to send us drawings for professional assessment.

Q8: I intend to do 5 axis machining work. What do I do first?

In the initial phase of initiating a 5 axis machining project, a 3D model in STEP/IGES and some basic technical requirements in terms of material, number, and other details of the design can be submitted to us. We shall help you with free DFM analysis and design solutions.

Summary

5 axis CNC machining is not a simple technological upgrade, but rather an innovation in making complex components. It not only overcomes several obstacles in terms of shape, materials, and accuracy, enabling the exact realization of design concept, but also cuts down costs thanks to one-stop machining.

Selecting a professional partner and capitalizing on the core competencies offered by 5 axis machining will provide double the benefit for your products in terms of both performance and costs. What JS Precision can provide you is not simply machine operating hours, rather engineering-proven, reliable, high-performance part solutions.

The time has come to shift your innovative designs from ideation to a highly efficient and deterministic manufacturing path.

→ Upload your complex part model to get expert DFM analysis and process recommendations from our engineers.

→ Organize a technical discussion, where our 5 axis expert team will analyze your project and help design an implementation strategy tailored to your needs.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com