5 axis CNC machining is key to solving the challenges of machining precision parts for many companies.

As an example, a complicated tooling fixture that needs five-side machining requires multi-setups and coordination of multiple machines, taking days and facing a high risk to the accuracy. Now, a single setup can complete it in hours with a single machine, improving accuracy by an order of magnitude. This is not only a technological leap but also a revolution in cost control.

However, to purchasing and engineering personnel, the biggest headache is that they cannot get the machining price for such complicated parts quickly and transparently. JS Precision was born to address this pain point.

From immediate quotations to cost breakdowns, selecting the right machining service to understanding the whole process of 5-axis CNC machining is clearly explained in this guide. It will make finding the best 5-axis CNC machining services easier.

Core Answer Summary

| Comparison Dimensions | 5-Axis CNC Machining Service | Traditional Multi-Process Machining |

| Quotation Speed | Real-time online quotation, receive a benchmark price within 30 seconds of uploading the model. | Traditional multi-process machining requires repeated communication and manual evaluation, taking hours to days. |

| Cost Transparency | The system automatically breaks down material and labor costs, ensuring transparent pricing with no hidden costs. | Traditional multi-process machining relies on supplier experience, resulting in opaque cost breakdowns and unclear negotiation opportunities. |

| Machining Efficiency | Completed in a single setup, significantly reducing total machining time and manual intervention. | Traditional multi-setup machining, using multiple machines, leads to long cumulative processing times and low efficiency. |

| Accuracy and Risk | Eliminates cumulative errors from multiple setups, resulting in high accuracy and excellent consistency. | Traditional multi-setup machining carries the risk of multiple positioning errors, leading to a relatively high scrap rate. |

| Most Suitable Scenarios | Prototype verification, small batches of complex parts, projects with tight delivery deadlines. | Suitable for large batches of standard parts with simple structures that can be distributed across different suppliers. |

5-Axis CNC Machining Guide: JS Precision Online Service And Instant Quotes

If you are in search of a reliable service for 5 axis CNC Machining, listen to the experience that JS Precision has to offer: with 15 years of deep involvement in the 5 axis CNC Machining industry, we have served over 1200 clients across such various industries including aerospace, medical equipment, and auto parts.

We can machine 32 kinds of commonly used materials, including aluminum alloy, titanium alloy, and stainless steel. We have machined engine blade parts for an aerospace client and achieved AS9100 quality certification on the first attempt with a 99.8% pass rate.

We have also processed artificial joint implants for medical clients, meeting ISO13485 standards and consistently ensuring machining accuracy of ±0.002mm.

Moreover, we have optimized more than 580 parts in DFM design and thus helped clients reduce machining costs by an average of 18%.

This guide is a distillation of our years of project experience, process techniques, and feedback from clients. Every suggestion has been validated through actual projects, so you can fully trust its professionalism.

If you need high-quality 5-axis CNC machining services, JS Precision is well prepared to handle this with extensive experience. Just upload your 3D CAD file and start a 5 axis CNC machining service process to get a fast, precise solution.

How Can I Get An Instant Quote For 5 Axis CNC Machining?

Want to know how to get a quote for 5 axis CNC machining as soon as possible? As easy as online purchasing, just three steps.

Step 1: Upload your design. You can drag and drop or upload 3D CAD files supporting STEP, IGES, X_T, etc. formats. The system will automatically analyze the geometric features of the part, such as surface complexity and the number of holes, to ensure no key information is missed.

Step 2: Specify your requirements. Choose materials, surface treatments, order quantity and key tolerances online. The system has an intelligent material library that automatically associates cost based on the selected materials.

Step 3: Get a quote. Powered by an AI-driven quote engine with real-time process analysis, it generates a transparent quote within 30 seconds listing the costs of materials, machining, and post-processing.

Behind this is an intelligent system with decades of accumulated experience by engineers in 5-axis CNC machining services, accurately assessing machining time and material waste to avoid inflated or undervalued quotations.

Beyond The Basics: What Truly Drives The Cost Of 5-Axis CNC Machining Services?

Once you have gotten the quotation, one may wonder what constitutes the cost estimate for 5-axis CNC machining services. The essential costs come mainly from five aspects:

1.Material Costs: Different materials bear radically different costs. For instance, aluminum alloy 6061 costs between $2-4 per pound, aerospace grade titanium alloy Ti-6Al-4V costs between $30-50 per pound, and specialty engineering plastic PEEK costs between $15-25 per pound. Material choice directly influences the basic cost.

2.Machining Time: This is the biggest variable, determined by the geometric complexity, size, and precision of the part. Machining simple flat parts takes approximately 10 minutes, machining shell parts with complex flow channels takes about 40 minutes because longer machining paths are required, the longer the machining time, the higher the cost.

3.Setup and Programming: CAM programming for 5-axis is more difficult and time-consuming compared with 3-axis. Programming of a complex part takes about 2 hours, but the cost is amortized after each setup and this cost percentage goes down considerably during mass production.

4.Post-processing and Finishing: Anodizing, electroplating, etc., increases costs. Ordinary anodizing costs $5 to $10 per piece, while nickel plating costs $15-20 per piece. The cost difference between different methods is great.

5.Lot Size: Large-scale productions allow the amortization of programming and setup costs. This cost percentage is roughly 30% for single-piece productions but less than 5% if the orders reach more than 100 pieces.

The table below helps compare the costs of different materials, therefore providing a better understanding of their impact on costs:

| Material Type | Unit Price Range (USD/lb) | Applicable Industries | Machining Difficulty |

| Aluminum Alloy 6061 | 2-4 | Automotive, Electronics | Low |

| Stainless Steel 316 | 8-12 | Chemical, Medical | Medium |

| Titanium Alloy Ti-6Al-4V | 30-50 | Aerospace, Medical | High |

| Specialty Engineering Plastics PEEK | 15-25 | Medical, High-End Electronics | Medium |

JS Precision will clearly indicate the cost breakdown of the 5-axis CNC machining services to you. Whether it is for a single prototype or large-volume 5 axis CNC machining, we can offer a good price quote.

Figure 1:Factors that affect CNC machining cost

The Mystery Of 5-axis CNC Machine Prices: What Determines Your Part Costs?

Many customers are concerned about the 5-axis CNC machine price, but in fact, machine configuration and performance are the core factors to influence, in four aspects specifically:

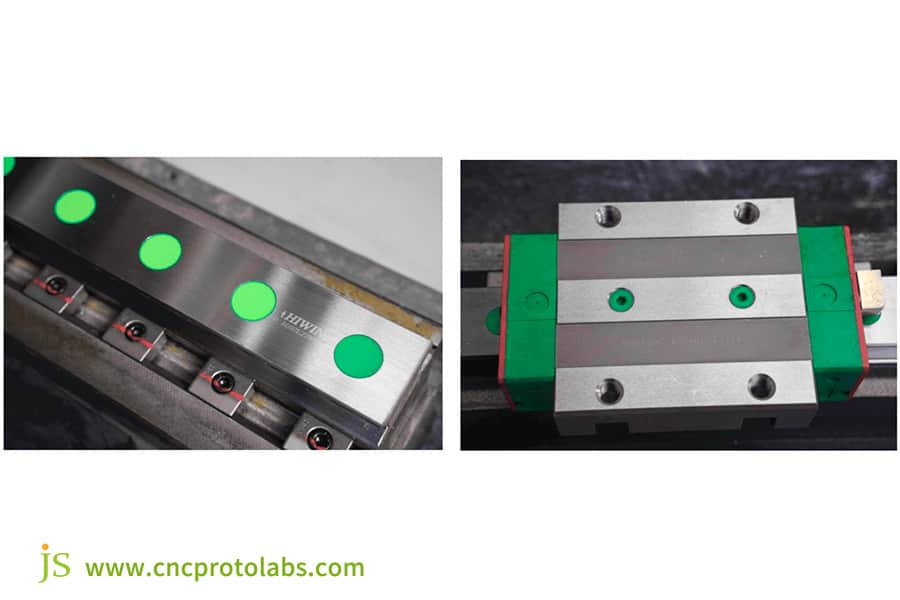

Precision and Rigidity: High-quality linear guides and ball screws are the foundation for long-term precision and are the most expensive components. Machines equipped with German Heidenhain linear guides cost $50,000-$80,000 more than those with standard guideways but guarantee a 5-year precision fluctuation of ≤±0.001mm.

CNC System and Software: The CNC system is the brain of the best 5 axis CNC machine. First-class systems from Heidenhain, Siemens, etc., cost $30,000-$60,000 more than standard systems but offer significantly improved programming efficiency and machining stability.

Automation Level: Robotic tool magazines and workpiece probes increase the 5 axis CNC machine price. A robotic tool magazine with 20 tools adds $20,000-$40,000 to the machine price but reduces tool change time and increases machining efficiency by 30%.

Table Size and Power: The greater the machining range and the larger the spindle power, the higher the price. Machinery with a table of 1000x800mm is at least US$ 15,000~US$ 30,000 more than a similar machine with a table of 500x500mm, machinery with 20kW spindles is US$ 10,000~US$ 20,000 more than that with a 15kW spindle, which is fit for machining large, high-hardness workpieces.

The following table shows how different configurations can affect the 5-axis CNC machine price for your reference.

| Configuration Factors | Configuration Level | Price Increase Range (USD) | Core Advantages |

| Precision and Rigidity | High-quality components. | 50,000-80,000 | Long-term stability of the precision. |

| CNC System and Software | Heidenhain top-of-the-line system. | 30,000-60,000 | Highly efficient programming, stable control. |

| Automation | 20-tool robot tool magazine. | 20,000-40,000 | Reduced tool change time, higher efficiency. |

| Table Size and Power | 1000x800mm/20kW | 15,000-30,000 | Machining large-size, high-hardness parts. |

If you want to know the best 5 axis CNC machine or 5-axis CNC machine price, JS Precision can provide professional advice. Our 5-axis CNC machining services can directly address your machining needs without the need to buy expensive equipment yourself.

Figure 2: Guide rails and screws. High quality, precision ground components ensure the accuracy and service life of the machine tool.

Navigating The Market: How To Choose Among 5 Axis CNC Machining Center Manufacturers?

When buying a 5-axis machine tool, facing so many 5 axis CNC machining center manufacturers, one should no longer look at the brand but whether these four aspects match:

1.Technical Matching:

The most expensive does not necessarily mean the best. Look into whether the manufacturer specializes in processing materials and parts for your industry.

For example, for the medical industry, it is advisable to choose a factory that has working experience in the processing of titanium alloy implants, in the automotive industry, choose a manufacturer specializing in aluminum alloy parts processing.

2.Quality Certification System:

Check if the manufacturing company is AS9100 and ISO13485 certified. This ensures high, consistent quality. They have stricter production control and quality inspection, hence they will reduce the risk of having defective parts.

3.Technical Support and Service:

Nearby technical support will be more contributive than distant "big brands." A local team would take less than 24 hours to visit the site to repair it in case of failure, while a remote team would take 3-5 days, which may disrupt production.

4.Return on Investment:

Instead of just looking at the initial 5-axis CNC machine price, we consider a comprehensive assessment of the performance, reliability, maintenance cost, and lifespan of the equipment. Machines whose prices are slightly higher but with low maintenance and a longer life may lead to lower total investment over 5 years.

Familiar with the strengths of various 5 axis CNC machining center manufacturers, JS Precision can help you indirectly choose suitable equipment. Meanwhile, our 5-axis CNC machining services directly meet your 5 axis CNC machining needs, saving your effort in choosing the manufacturer.

Performance Showdown: Which Is The Best 5 Axis CNC Machine For Your Project Needs?

With the right manufacturer selected, you won't have to bother about specifications for choosing the best 5 axis CNC machine. Simply categorize by project type for a more accurate fit to your needs:

1.High Dynamic Precision Type: Suitable for aerospace aluminum alloy parts, such as engine mounts and blades. These components require fast tool response and ultra-high contour accuracy. High dynamic precision machines achieve ±0.003mm accuracy at high speeds, preventing vibration from affecting quality.

2.High Rigidity Type: The medical implant titanium alloy, such as artificial joints and spinal fixation plates, can be done with high hardness. The machining has to bear large cutting forces. High rigidity machine tool bed and spindle can reduce deformation, ensure dimensional stability, and extend tool life.

3.Cost-Effective Type: Suitable for automotive electronic parts, such as sensor housings and connectors. These parts require moderate precision but are cost-sensitive. Cost-effective machines guarantee ±0.01mm accuracy while controlling processing costs, making them suitable for mass production.

JS Precision offers a wide matrix of equipment in these three categories, making it capable of matching the best 5 axis CNC machine to various projects. High-dynamic-precision machines are used for aero-engine blades, while medical artificial joints require high-rigidity machines to tackle the job efficiently and precisely.

JS Precision can provide the best 5 axis CNC machine for different projects. Whether you want to machine aerospace aluminum alloy parts or medical titanium alloy parts, our 5-axis CNC machining services provide precision machining to help reach your project goals.

Figure 3: Longmen type five axis CNC machine tool. It has a highly stable structure and usually has a wide worktable and side supports.

The Strategic Edge: How Does Multi-Axis CNC Machining Deliver Cost Savings?

Besides the high precision, choosing 5-axis machining will save many "hidden costs," which companies will gain in the long run:

Reduced Fixture Costs:

With each setup, fewer fixtures are required, or none at all. For example, multi axis CNC machining requires 1 simple fixture per setup (cost: $150) compared to 4 sets of fixtures for traditional 3-axis machining of complex appliance housings at a cost of approximately $800 each, a saving of $650.

Accelerated Time to Market:

Shortening the setup and machining cycles offers quicker product launches. For instance, a customer was developing a smartwatch casing, which required 3 weeks for the first sample by traditional 3-axis machining. With optimization using multi axis CNC machining, it was completed in 1.5 weeks, bringing the product to market 1.5 weeks ahead of schedule.

Fewer Steps in Assembly:

Multi axis CNC machining assembles multiple parts into one structure to save assembly cost and time as well as improve reliability. For example, a customer's machine bracket had an original assembly with 5 pieces that took 25 minutes per set and posed a potential loosening risk. Following integration, it required no assembly and hence avoided the potential risk.

Scrap Rate:

Fewer clamping operations reduce the possibility of scrap resulting from positioning errors. A customer machining electronic casings needed 3 clamping operations using traditional 3-axis machining and was experiencing a 5% scrap rate.

Multi axis CNC machining was able to reduce this to just 1% after a single clamping operation. On an order quantity of 1000 units, there was significant cost savings as a result.

The following table provides a cost-savings comparison of multi axis CNC machining versus traditional 3-axis machining:

| Cost Type | Traditional 3-Axis Machining | Multi-Axis CNC Machining | Savings Per Order (100 pieces) | Cost Savings (USD) |

| Jig Cost | $800/set | $150/set | 81.25% | 650 |

| Cycle Time | 3 weeks | 1.5 weeks | 50% (Based on downtime loss of $1000/day). | 10500 |

| Assembly Time | 25 minutes/pc | 0 minutes/pc | 100% based on labor rate of $20/hour. | 833 |

| Scrap Rate | 5% | 1% | 80% (Based on unit cost of $50). | 2000 |

Case Study: How Integrated 5-Axis Machining Reduces High-End Medical Monitor Housing Costs By 40%

The aforementioned cost savings are not just empty words. Let's see how integrated 5 axis CNC machining helps customers reduce costs:

Customer Pain Points

The new portable monitor motherboard shell of a well-known medical equipment manufacturer was originally designed to be assembled with screws consisting of 5 parts: 1 aluminum base, 3 side walls, and 1 top cover.

- High Cost: Each of the 5 parts needs to be individually programmed and machined and then finished, up to 1,500 a set, well out of the 1,000 budget.

- Seal Risk: Several seams can allow liquid into the part, complicating meeting the IP54 protection rating and impacting reliability in emergency medicine.

- Low Assembly Efficiency: Assembly is highly complex, taking 25 minutes per set. With an 8-hour workday, it can only attain 192 sets assembled in a day, hence cannot fulfill mass production demands.

JS Precision Solutions

Our engineers support customers from the DFM design stage with value-added services:

1. Design Optimisation:

We work in close liaison with the client's engineers to redesign 5 parts as one single integrated housing. At the same time, the housing design will include cable clips, heat sinks, and interface sockets, which were installed separately as features. High-performance 6061 aluminum alloy is selected for cost-effectiveness, achieving both strength and cost control.

2. 5-Axis Machining Strategy:

Using our high-rigidity 5 axis machining center, all external curved surfaces, internal cavities, complex flow channels, and screw mounting holes at various angles of the housing can be machined in one setup while machining accuracy is controlled within ±0.005mm to ensure precise feature placing.

3. Process Optimization:

Intelligent CAM programming optimizes toolpaths to reduce idle travel distance. Dedicated cutting tools for aluminum alloy reduce the processing time of a single housing from 40 minutes to 26 minutes, which is 35% less in machining time.

Results and Data

Returns for the client after collaboration were higher than expected:

- Significantly reduced costs: 80% reduction in quantity of parts, cost per set is reduced from $1500 to $900, a 40% reduction.

- Leap in quality and reliability: seamless assemblage, IP56-level sealing, and 99.9% reliability.

- Doubled supply chain efficiency: Changing from "multiple-piece procurement and internal assembly" to "one-stop delivery," the time taken to assemble was almost zero, shrinking the delivery time of projects from 4 weeks to 2 weeks.

- Significantly reduced scrap rate: One-time clamping reduces positioning errors, hence reducing the scrap rate from 3% to 0.5%, based on an order of 1000 sets, this would mean a reduction of 25 scraps and a saving of $3750.

Figure 4: 5-axis cnc machining services

JS Precision's 5-Axis CNC Machining Services: Your Online Manufacturing Engine

You are already familiar with our services. "Online and digital" is the core of 5-axis CNC machining services at JS Precision: it makes the whole customer experience smooth, without any fussy procedures.

To use 5-axis CNC machining, three easy steps can be followed:

- Step 1: Upload your 3D CAD file, supported formats include STEP, IGES, and X_T. In 10 minutes, the system will output the DFM analysis report, pointing out cost or accuracy issues in the design, such as unnecessary deep cavities or too-small fillets.

- Step 2: Upon confirmation, view the DFM report online to specify materials, surface treatments, quantity, and tolerances. Instant quotes will be produced, and there are no hidden costs involved in this process.

- Step 3: Confirm the quotation and place your order directly. You can pay the deposit to start production. Get real-time updates on a dedicated page all the way from raw material procurement to logistics and delivery.

This is an online model quite different from traditional manufacturing. The traditional way requires repetitive communication, taking 3-5 days, while our model finishes it all in one hour, from uploading files to placing the order.

One customer uploaded the files at 9:00 am, confirmed the DFM report at 9:10 am, confirmed requirements and quotation at 9:15 am, placed the order at 9:20 am, and saw production arrangements at 9:30 am-highly efficient.

FAQs

Q1: What is the lead time for the average 5-axis machining project?

The prototype lead time is usually 1-2 weeks. In mass production, it depends on the quantity you ordered. Once you upload the files for an instant quote, the quote will have the accurate lead time.

Q2: What file formats do you accept for an instant quote?

Neutral 3D formats like STEP, IGES, and X_T are ideal because these formats hold the geometric features and dimensional information of the model best for more accurate analysis and quotation.

Q3: Can 5-axis machining create undercuts and deep cavities?

Yes, this is the very essence-the central advantage-of 5 axis CNC machining. Either the swivel head or the rotary table allows the tool to reach such unreachable areas at their most optimal angle and hence machines them accurately.

Q4: How does the accuracy of 5-axis machining compare to 3-axis?

Since 5 axis CNC machining reduces the number of setups and eliminates datum conversion errors, its positional and contour accuracy is usually much higher than 3-axis machining for higher precision needs.

Q5: Is 5-axis machining only for complex parts?

Not at all. Even for simple parts with multi-faceted machining requirements, 5 axis CNC machining can increase efficiency and accuracy with just one setup, it is not just applicable to complex parts.

Q6: Do you provide DFM feedback on my design?

Of course! Your instant quote includes a free Design for Manufacturing report from the engineers that will provide suggestions to optimize your design and reduce machining costs. This will also enhance production feasibility.

Q7: What is the minimum quantity order of your services?

We support both single prototype and mass production, with no mandatory minimum order quantity (MOQ) requirement. We can flexibly arrange production according to your actual needs.

Q8: Can you handle both prototyping and production volumes?

Yes, we offer end-to-end 5-axis CNC machining services, from rapid prototyping to large-scale mass production. We assure quality from design to the product and meet the needs at all stages.

Summary

Nowadays, 5-axis CNC is no longer an unapproachable leading technology, but a necessary tool in the competitive development, cost reduction, and unleashing of smart manufacturers' designing potentials.

JS Precision is committed to breaking technical barriers. With our intelligent online platform and rich engineering expertise, we offer instant quotes and cost-effective multi axis CNC machining services that will enable you to enjoy all the benefits of this technology with absolutely zero barriers to entry.

Don't be troubled by complex parts and tedious inquiry processes anymore. Just drag and drop your design files onto our quotation page now and enjoy our instant, transparent, professional 5-axis machining quote service. Thanks to our online service process, the completion of orders becomes easy, making precision part machining much easier and more efficient.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com