ABS plastic and acrylic are two iconic plastics used in product manufacturing, but regarding 3D printing, they possess quite contrasting characteristics, printing techniques, and uses.

ABS is world-class for its strength and toughness, while acrylic occupies a niche market with crystal clarity. ABS plastic or acrylic: what do you use in your 3D printing project? What are they differing with if used in 3D printing? The incorrect choice can translate to part breakage, wasted prints, and even increased costs.

This guide will provide you with the complete comparison of differences between the two, help you make your material choosing process neater, and achieve a smoother 3D printing project and avoid errors.

Summary Of Core Answers

| Comparative Dimensions | ABS | Acrylic |

| Core Properties | Impact-resistance, strong, and slight scratch-resistance. | Very transparent, brittle, and scratch-prone. |

| 3D Printing Suitability | Excellent, one of the most widely used material for FDM printing. | Good, with some specialized materials available, but with greater challenge. |

| Printing Difficulty | Medium, requires heated build plate, tends to warp easily. | High, extremely prone to warping and cracking, with precise temperature control. |

| Post-Processing Capabilities | Can be easily sanded, polished, and acetone-fumigated to achieve smooth finish. | Easy to sand and polish, and achievable to crystal clear with specialist solvents. |

| Common Uses | Functional components, enclosures, gears, LEGO bricks. | Optical models, light boxes, display stands, transparent decorative items. |

| Material Cost | Low cost, very cost-effective. | Moderate cost, usually higher than ABS. |

Which Is Stronger And More Resilient? JS Comparison Testing Uncovered

JS Precision has over 10 years of practical experience in comparing the performance of 3D printing materials, and has performed specialized ABS and acrylic testing for over 300 customers from 20 industries including automotive, drones, and electronic products.

For example, when testing for an automotive parts manufacturer, we compared 12 ABS filaments and 8 modified acrylic filaments against 15 critical performance indicators like impact strength and flexural modulus across the temperature range of -20°C to 60°C.We eventually helped the client select a material that would satisfy the vibration and temperature fluctuation in the in-vehicle environment.

We have also optimized the ABS warpage control scheme for FDM 3D printing technology. By adjusting the heat plate temperature and print chamber encapsulation, we lowered the client's ABS print failure rate from 18% to 8%. For acrylic, we developed a step-by-step cooling protocol to reduce cracking caused by internal stress, which saved the client over $50,000 in wasted material.

This guide summarizes our test data and project history over the years. Each finding is illustrated by real-life examples. You may count on its practicality and professionalism.

With over 10 years of experience testing 3D printing materials, JS Precision stands apt to judge the difference in performance between ABS plastic and acrylic, providing support for your 3D printing parts selection. Allow us to take care of customized testing solutions.

Meet The Two Protagonists: Engineering Warriors Vs. Optical Artists

Both acrylic and ABS plastic are the two widely used materials in 3D printing with varied characteristics, both excelling in different applications.

ABS plastic

Being a vintage engineering plastic, it is the leading application in the 3D printing industry, particularly in application where structural integrity is required. Its most common 3D printing technology is FDM (fused deposition modeling).

The majority of the industrial-grade 3D printing parts use ABS plastic as it meets the requirements for the majority of functional parts.

Acrylic

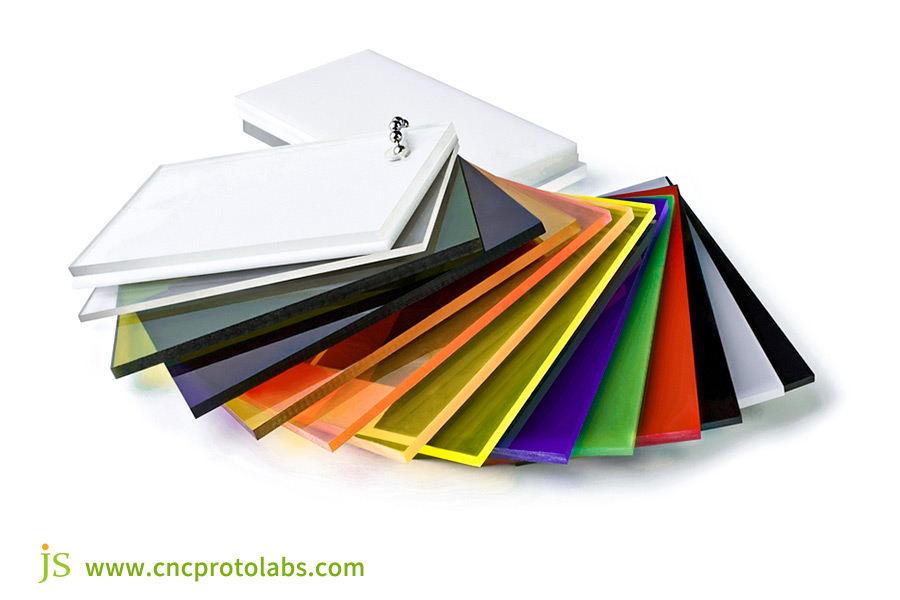

Its best quality is its superior optical clarity with light transmission of up to 92%, which is where it gets its nickname "plexiglass." Pure acrylic filament is difficult to utilize in 3D printing, so they employ the altered acrylic copolymer filaments.

These filaments have better printing performance, reduce cracking and warping during printing, and give higher-quality uniformity of clear 3D printing parts.

If you want to have custom 3D printing parts, JS Precision's custom 3D printing manufacturing service can recommend suitable ABS plastic or re-engineered acrylic filaments based on your need, and your printed parts will be exactly what you require.

Eight Core Differences: The Key To 3D Printing Success

It is important to understand the fundamental differences between ABS plastic and acrylic in order to undertake successful 3D printing. The following will detail the differences between the two on seven dimensions and then present the main information in a short table.

Mechanical Properties

ABS plastic is hard and impact-resistant, resistant to breakage when subjected to external pressures, and it is suitable for structural parts.

Acrylic is brittle and impact-resistant, breaking very easily when subjected to external pressure, and it is unsuitable for applications that are subjected to impacts.

Thermal Properties

ABS plastic has a heat deflection temperature of approximately 90-110°C, maintaining some of its shape stability even under high temperatures.

Acrylic, with a heat deflection temperature of approximately 80-90°C, lower heat resistance and deforms above this temperature range.

Differences in Printing Behavior

ABS plastic is prone to warping, primarily due to uneven cooling upon printing and causing uneven shrinkage. It can be eliminated by the use of a hot build plate between 80-120°C and a closed print volume to minimize temperature fluctuation from air currents.

Acrylic is prone to internal stress, leading to cracking, because internal stresses cannot be relieved well during curing. The fix is to control the cooling rate, for instance, by slowing down the cooling fan speed after printing to avoid big temperature gradients between sections of the part.

Interlayer Adhesion

ABS plastic is mid-range. Its Z-axis strength under the same conditions, when printed, is mid-range, and prolonged stress can cause layer separation.

Acrylic has better interlayer adhesion, resulting in tighter interlayer bonding and higher Z-axis strength than ABS plastic, resulting in a more stable overall part structure.

Post Processing and Bonding

ABS plastic is easy to post process. It can be bonded and polished with acetone, which melts the surface of the ABS, holding the parts in place better and leaving the surface smoother when polished.

Acrylic is harder to post process, since it requires specialized solvents such as chloroform for bonding. Commercial polishes need to be applied to polish it, and the process needs to be controlled in order not to damage it.

Weathering and UV Resistance

ABS plastic has poor weather resistance and is prone to yellowing due to UV radiation during outdoor use, which in turn affects its appearance and performance.

Acrylic has an excellent resistance to UV and is less likely to discolor and age even after a long period outdoors, hence an ideal option for outdoor 3D printing parts.

Safety

ABS plastic releases trace amounts of volatile organic compounds (VOCs) such as styrene during printing, which, if inhaled over a long time period, can be toxic.

While acrylic releases less VOC when printed, its proprietary adhesive and polishing solvents are irritants, so caution needs to be taken when handling them.

The following table gives a synopsis of the most important differences between the two:

| Core Difference Dimensions | ABS Plastic | Acrylic |

| Mechanical Properties | Outstanding toughness, good impact resistance. | High brittleness, low impact resistance. |

| Heat Deflection Temperature (°C) | 90-110 | 80-90 |

| Chief Printing Issues | Prone to warping. | Prone to cracking due to internal stress. |

| Weather Resistance | Poor, yellowing when outdoors. | Excellent, outstanding UV resistance. |

| Post-Processing Ease | Easy (acetone can be applied). | Hard (specialized solvents/polishing chemicals required). |

If you need help with managing the material selection problem with 3D printing, JS Precision is here to offer professional technical support. We can provide the accurate material recommendation based on eight main differences, helping you to finish 3D printing parts effectively.

Detailed Cost Analysis: The Real Costs Behind The Per-Gram Pricing

When choosing 3D printing material, do not consider the surface cost alone and include the underneath costs. Here, below, we compare the actual costs of ABS plastic and acrylic from three aspects: direct cost, indirect cost, and equipment energy consumption.

| Cost Type | ABS Plastic | Acrylic |

| Direct Cost (per kg) | Relatively low, about $20-30 per kg, suitable for batch 3D printing. | More costly, about $30-45 per kg, with a higher per-print cost than ABS. |

| Indirect (Failure) Cost | Low print failure rate of approximately 5%-10%, primarily as a result of warping, with minimal waste of material and indirect cost. | High print failure rate of approximately 15%-25%, primarily as a result of internal stress cracking and first-layer adhesion failure, with material waste and very high indirect costs, at least double the overall costs. |

| Equipment and Energy Expenses | Low equipment requirements, a standard FDM printer will do. The heated build plate and nozzle require moderate amounts of energy, so additional equipment is not needed. | High equipment demands require high temperature stability (within ±2°C) and stable build plate heating. Some printer modification is required in some cases. Energy consumed is 10%-15% greater than when printing with ABS, i.e., increased equipment and energy expenses. |

JS Precision's online 3D printing services can help you control the 3D printing price. We will optimize material usage according to your needs, reduce failure waste, and enable you to obtain high-quality 3D printing parts at a reasonable cost.

The 3D Printing Test: Who Is The Champion?

ABS plastic and acrylic are competing in 3D printing with their advantages and limitations. The choice between them should be made based on project requirements.

ABS Plastic: The "Benchmark Material" for 3D Printing

Advantages:

The 3D printing technology is established, and there are numerous printing parameters to draw on in the market, making it easy for a beginner. Post-processing techniques are conventional and effective, e.g., acetone fumigation, which can smooth the surface.

And there are many ABS wire brands on the market, making it easy to purchase. Furthermore, 3D printing parts fabricated from ABS plastic possess adequate toughness and meet most structural requirements.

Challenges:

Warping is the most challenging when ABS 3D printing, especially when producing large parts. Extra time and energy are spent controlling warping, through modifications of printing parameters.

Acrylic: The Struggle for Clarity

Advantages:

Items printed with success have excellent transparency, something ABS plastic cannot achieve. It is thus appropriate to 3D print objects that require transmission of light, e.g., optical windows and display coverings.

Challenges:

Strongly temperature- and print speed-sensitive. Small drop in temperatures produces poor interlayer adhesion, and extremely high speeds can easily induce internal stresses, requiring repeated adjustment of printing parameters and high technical requirements for operators.

Professional advice:

If you need transparency but are unable to manage pure acrylic filament, look at ASA (ABS with UV resistance) or PETG as a compromise option. ASA provides good UV stability and comparable performance to ABS, PETG prints more easily and provides some transparency, satisfying some light transmission specifications.

Decision Guide: 5 Key Questions To Help You Make The Correct Material Choice

Before you click the "Print" button, ask yourself these questions to quickly identify the right material.

1. What are your essential requirements?

If you require 3D printing parts with high structure strength and resistance against impacts, like drone casings or mechanical mounts, use ABS plastic. If you require extremely transparent components, like see-through windows or optics, use acrylic.

2. What is the targeted use environment?

If the part will be used outdoors and requires UV and weather resistance, acrylic is a better choice. If it will be used indoors at room temperature, ABS plastic will meet your needs and be more cost-effective.

3. What is your tolerance for printing difficulty?

If you are a beginner in 3D printing or do not wish to spend much time fine-tuning parameters, use ABS plastic due to the more developed printing technology and small failure rate. If you are an experienced printer, possess rich experience with complicated adjustments, and need a clear effect, use acrylic.

4. How much work are you willing to do in post-processing?

If you're not willing to spend a significant amount of time processing, ABS plastic would be a better choice, it can be bonded and smoothed using acetone. If you're willing to do more work to process the part to make a transparent effect, acrylic would be a good choice.

5. What is your budget?

If you have a tight budget and want to be able to control the 3D printing price, employ the use of ABS plastic, which has lower indirect and direct prices. If you have ample funds and want to create a clear effect, use acrylic.

JS Precision's custom 3d printing manufacturing service will construct a customized 3D printing solution according to your answers, providing end-to-end service from material selection to parameter setup so you can complete your project with ease.

Beyond FDM: When ABS And Acrylic Meet Other 3D Printing Technologies

Aside from the traditional FDM 3D printing technology, ABS plastic and acrylic also find applications in other printing technologies. Familiarizing yourself with these will generate more ideas for your project.

SLA (Stereolithography) Printing

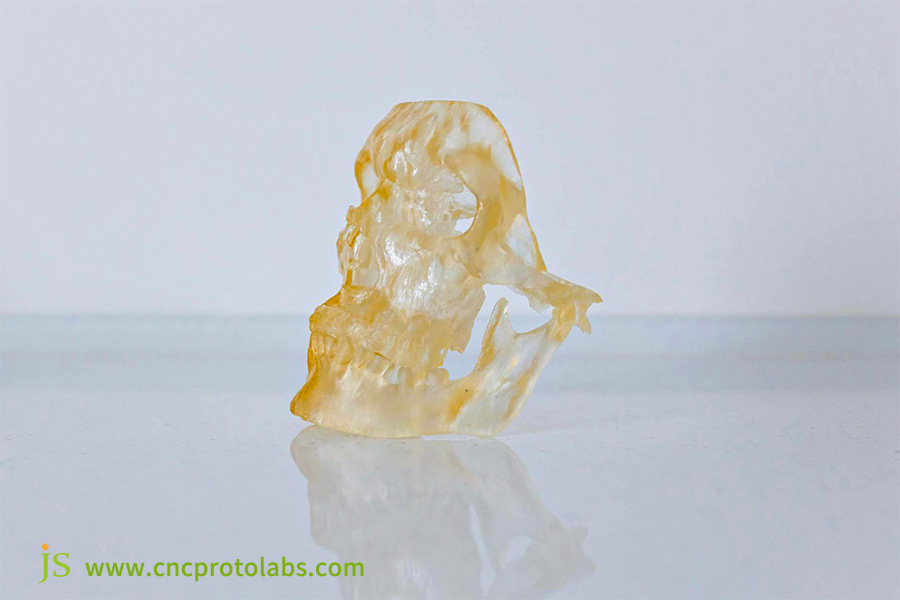

In SLA technology, "acrylic" is usually a photosensitive resin. Cured out of this resin is very transparent parts with the characteristics of conventional acrylic, but with a different printing mechanism than FDM.

Acrylic parts made through SLA give higher accuracy and a more polished finish, hence used to print fragile optical parts. ABS plastic is not that extensively applied in SLA and is applied more extensively in FDM.

Material Jetting

Similar to PolyJet technology, this technology can print multiple materials in a single pass. It can be achieved in the future to achieve the integration of "ABS-like" hard parts and "acrylic-like" transparent parts.

For example, when manufacturing a part, the main body can be made using a tough ABS-like material and the localized transparent area with a clear acrylic-like material. This eliminates post assembly, enabling better part integrity and manufacturing efficiency.

Material selection is not limited to FDM process. Choosing the right technology and material combination based on the accuracy and performance requirements of the printed parts can render the product competitive.

Case Study: Creating A Transparent Housing For An FPV Image Transmission Antenna Of A Drone

Customer Needs

A racing drone manufacturer requires a drone FPV antenna housing, with three specific requirements:

- Extremely impact and drop resistant and should withstand a 3-meter drop without sustaining any damage five times.

- A transparent plastic window at the top to clearly display the inside LED status indicator with a light transmission rate of at least 85%.

- Lightweight, with a combined weight of below 20 grams so as not to affect the flight speed of the drone.

JS's Solution and Iterations

Version 1 (All-ABS Printing):

We printed the housing using high-strength ABS filament. The part met the strength of 25kJ/m² in the impact test, passing the requirement. But being opaque, ABS plastic did not allow the LED light to be seen from the top.

A hole had to be incorporated, adding more weight to the model, making it 23 grams, which was more than the customer needed. The incorporation of the hole exposed the model to dust and water, which would reduce the lifespan of the LED and the quality of the display.

Version 2 (All-Modified Acrylic Printing):

The transmittance of the printed housing, which was achieved using highly transparent modified acrylic filament, was 90%, fully meeting the LED display requirement without the weight going beyond 18 grams. Acrylic is very brittle, with an impact strength of just 12kJ/m². The third impact test caused it to break and not meet the required durability.

Final Solution (Hybrid Design):

The body was printed in ABS plastic wall thickness 1.2mm for strength. The transparent window was printed independently with high-transparency acrylic filament of 0.8mm thickness as an embedded component.

Assembly was carried out using a snap-fit method with ABS-specific adhesive to securely embed the acrylic window within the ABS body. The overall weight was kept constant at 19.5 grams, meeting strength, light transmission, and light requirements.

Results

The housing survived 10 3-meter falls without damage, and the LED light was visible from outside the acrylic window. The bulk customers experienced 60% lower product failure rates.

This example shows that selecting materials from a position of understanding the functional requirements of 3D printing parts is better than using a single material to try to repair everything, and can even lead to a better performing product.

Final Decision: What Plastic Should You Use?

The Situation Of Choosing ABS Plastic

First, let's clarify what is ABS. It is a 3D printing material with strong toughness, good impact resistance, and mature printing technology.

If you need to create 3D printing parts that are structurally robust and can withstand impact, such as mechanical brackets or device cases, if you're a beginner in 3D printing and desire to minimize printing intricacy and failure rates.

Or if you're tight on your budget and you want to control the 3D printing price, then ABS plastic is a suitable choice. Besides, if the parts will be used indoors at room temperature, ABS plastic also meets your performance requirements.

The Situation Of Choosing Acrylic Plastic

If you need high transparency in printed parts, e.g., optical windows or clear display enclosures, or the parts will be used outdoors and need to be UV and weather resistant, and you have sophisticated 3D printing skills and can live with complicated print setup and post-processing, then acrylic plastic is suitable.

Thinking of a Third Option, PETG/ASA

If you can't choose between ABS and acrylic, use PETG or ASA instead. PETG is easier to print,with a strength between the two and is ever so slightly transparent, so it's a good option for whenever you need light transmission and don't have time to debug much.

ASA has great UV resistance similar to ABS plastic, making it a suitable 3D printing part for outdoor use and avoiding the problem of ABS yellowing outdoors.

FAQs

Q1: When printing with acrylic filament, the adhesion of the first layer always fails. What do I do?

This is generally due to low build plate temperature or improper nozzle height. We recommend that the build plate temperature be at 90-100°C, a glass build plate be used, and a special PVA adhesive be applied to enhance adhesion. We recommend that the nozzle height be such that there will be a 0.1-0.2mm gap between the nozzle tip and the build plate.

Q2: Can acetone be used to polish acrylic 3D printing parts?

No! Acetone melts acrylic, causing cracks (stress cracking) on the surface of the part and degrading the structure and clarity of the part. Acrylic 3D printing parts need to be vapor-polished with trichloroethylene or a commercial acrylic polish. It must be performed in good ventilation, and protective equipment should be employed to avoid skin contact and inhalation of the solvent.

Q3: Is ABS printing hazardous since it smells so pungently?

ABS printing releases trace amounts of volatile organic compounds (VOCs) such as styrene. Prolonged breathing of these substances causes deleterious effects on the respiratory system and body. Hence, it is recommended to print in a sufficiently ventilated area or set an air purification system on the printer. Avoid standing for long hours next to the printer to minimize inhalation of poisonous substances.

Q4: Is there any 3D printing material that possesses the toughness of ABS, but the clarity of acrylic?

There is no such "two-in-one" material yet that embodies the best of both worlds. Translucent PETG and polycarbonate, however, offer a compromise in some uses. Translucent PETG is print-friendly, has strength up to the same as ABS, and offers some transparency. Polycarbonate offers good transparency and high strength but is slightly more challenging to print.

Summary

Choosing ABS or acrylic is not a simple battle of superiority or inferiority, but a matter of thoughtful consideration of your project needs, technical capabilities, and desired output. As long as you combine the functionality, usage environment, and technical experience of 3D printing parts, you can find suitable materials.

JS Precision offer online 3D printing service in a number of materials, such as ABS plastic. We provide complete control for guaranteeing the quality of your 3D printing parts, but also with reasonable 3D printing prices and a hassle-free simple ordering procedure.

Contact us immediately. Just give us your design blueprints, and we'll promptly undertake production, guaranteeing your project is optimally executed.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com