Gear Generating represents the core technology for modern high-precision gear manufacturing.

Think of the huge transmission system in a heavy-duty mining truck, where the spiral bevel gears bear loads of hundreds of tons, or the minuscule planetary gears on a precision medical robotic arm, guaranteeing movements accurate to the micrometer level-they may well both come from the same fundamental manufacturing process.

This is by no means an accident, but rather that's the very appeal of Gear Generating technology. It happens to be today's mainstream for gear machining and also represents a high-precision, high-performance gear.

The following will give a detailed explanation of the principles, steps, and applicable scenarios of this process, it will also introduce JS Precision's services and case studies to help you master the key to how to make gears and find the gear manufacturing solution that suits your needs.

Core Answer Summary

| Comparison Dimensions | Best Gear Types for Gear Generation | Key Advantages of Gear Generation Processes | JS Precision's Value-Added Services |

| Processing Principle | Involute cylindrical gears, helical gears, herringbone gears. | Continuous generating method, simulating the gear meshing with high precision and good tooth surface finish. | CAD/CAM integrated simulation for optimum processing. |

| Efficiency and Flexibility | Complicated tooth profiles, including spiral bevel gears and cycloidal gears. | One tool can process gear teeth of the same module but different numbers, fast changeover. | It supports flexible production from small batches to large batches. |

| Precision and Performance | Gears that call for high requirements in noise, efficiency, and life span. | Accurate tooth profile, smooth transmission, ideal contact area, low noise. | Provides gear grinding service as the final processing to achieve the highest precision. |

| Customized Capabilities | Spiral bevel gears and gears with non-standard teeth. | The tooth profile is modifiable by programming and ideal for special applications. | One-stop capability for gear manufacturing, from design consultation to heat treatment and grinding. |

JS Precision: Gear Generation Optimized By Precision Machining Experience

With more than 15 years of practical experience in the field of Gear Machining, JS Precision provides for the optimization of gear. The core strength of our Gear Generating process. We serve customers in many industries such as aerospace, medical devices, and high-end electromechanical engineering.

For instance, we have produced 0.5mm small-module precision gears for a medical device manufacturer by using a strict process of Gear Generating to achieve a product yield rate of 99.8%. We have also machined precision helical gears with an AGMA 13 class for a high-end electromechanical company requiring extreme speed and low noise.

We are not only familiar with the machining characteristics of various gears, but also established a complete set of quality control systems. From CAD model import to final product inspection, every step is overseen by professional engineers.

For example, when facing heat treatment deformation, through our proprietary process, the gear common normal variation could be controlled to ≤8μm, which is hardly achieved by many competitors.

The following guide is a summary of our years of experience in Gear Machining and Gear Generating. Its content is authentic and reliable, providing you with practical technical references.

If your company is facing problems such as insufficient gear precision or low machining efficiency, please don't hesitate to contact JS Precision. Please describe your gear application scenario and precision requirements, and we can make a preliminary assessment about whether Gear Generating is suitable for you, offering free technical advice in the process.

What Is Gear Generating? A Modern Process Beyond Traditional Cutting

In gear machining, gear generating is a very effective and highly accurate method, and it is one of the key technologies answering the question of how to make gears.

Its basic philosophy is to "generate" an accurate tooth profile through a simulated meshing motion between the cutting tool and gear blank. The basic concept of "motion creates shape" is fundamentally different from a conventional profile machining method.

Traditional profile machining directly copies the shape of the cutting tool in order to machine the tooth profile, and the precision of the machined tooth profile is affected by the tool shape error. Gear generating is different because it can allow the tooth profile to gradually form through the continuous meshing motion of the cutting tool (such as a hob) and the blank.

The tooth profile can be generated for precision requirements by the coordinated motion of the hob and the blank during the machining of helical gears.

This unique machining principle is the reason why Gear Generating has become the mainstream technology in modern high-efficiency gear manufacturing. In particular, it not only guarantees high tooth profile accuracy but also adapts to gear machining with variable numbers of teeth, playing an important role in gear machining.

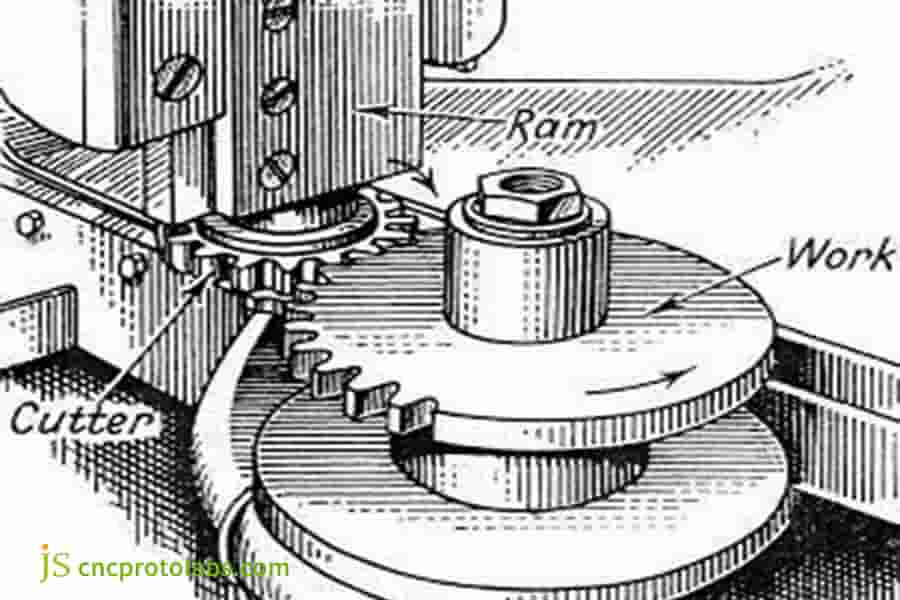

Figure 1: The Gear Generating method utilizes the specific relative motion between the workpiece gear and the tool during the machining process.

Gear Generating And Gear Forming: How Do They Differ From Each Other?

Gear generating and gear forming are the common methods of machining in gear machining. They are quite different in both principle and precision, as listed in the table below.

| Comparison Items | Gear Generating (Generation Method) | Gear Forming (Forming Method) |

| Machining principle | The tooth profile is generated based on the simulated meshing motion between the tool and workpiece. | The tooth profile directly copies the shape of the tool during machining. |

| Cutting Continuity | Continuous cutting, high machining efficiency. | Intermittent cutting, relatively low machining efficiency. |

| Precision Grade | High precision, ranging from AGMA level 12 and above. | The precision is limited, usually up to AGMA level 10. |

| Tool Flexibility | Good flexibility, one tool can machine gears of the same module but with different numbers of teeth. | Strong tool specialization, a given type of gear must be machined using a specific tool. |

| Applicable Cases | High-precision, high-complexity gears such as aerospace gears, precision instrument gears. | Standard gears with low requirements or large quantities, such as spur gears used in general machinery. |

The actual choice between gear generating and gear forming depends on the application scenario of gear, precision requirement, and production volume.

If you are not sure whether gear generating and gear forming is more suitable for your gears, just upload the drawings of your gear design. The JS Precision engineer will suggest the best processing method according to the details of the drawing and your actual requirements so that you can avoid waste caused by improper selection.

Gear Generating Process: What Are The Basic Steps?

Gear generating process is a very rigorous and complex process. Every step in gear generating directly influences the final precision and quality of the gear. At JS Precision, we divide the gear generating process into three key steps to ensure that each gear meets the requirements.

Step One: Design and Programming

This is the exact starting point of gear generation process.

We import the customer-provided gear CAD model, analyze and confirm key parameters such as the tooth profile, module, and number of teeth, and then use professional CAM software to write the machining program and simulate the tool path with repeated parameter adjustments to avoid interference, ensuring accurate path accuracy.

Step Two: Machine Tool Setup and Clamping

The accuracy of machine tools and fixtures directly determines the stability of machining.

A high-precision CNC gear machining machine will be selected, with some parameters of spindle speed and feed rate calibrated. In clamping, special tooling will be used for the fixation of the blank, considering coaxiality and perpendicularity in order to minimize the machining vibration.

Step Three: Generating Cut and Online Inspection

This will be the step that moves the tool and workpiece along the pre-set trajectory for "generating" the tooth profile.

An online measurement system will be activated during machining to monitor real-time tooth profile accuracy and pitch deviation indicators. If the data exceeds the tolerance, the system will automatically stop. Engineers will analyze and adjust parameters.

Want your gears to be machined via a standardized gear generating process? Kindly submit your gear machining requirements, and JS Precision will create a detailed gear generating process plan for you, from design to programming right through to final inspection, transparent and traceable, allowing clear comprehension of the progress and quality of every step in the process.

The Gear Generating Process Is Most Beneficial To Which Type Of Gears?

Not all gear types can be processed in the Gear Generating process in gear machining. Those that benefit from it include the following because Gear Generating directly addresses their machining challenges:

High-precision helical gears and worm gears:

Tooth direction and contact areas of the gears have very high requirements. Through the simulation of the meshing, Gear Generating precisely controls the tooth direction parameters to ensure that the area of meshing contact is uniform, wear is reduced, and the transmission efficiency is improved.

Complex spiral bevel gears:

Spiral bevel gears have complex tooth profiles. Gear Generating uses specialized machine tools and cutters to generate the tooth profile with a high degree of precision, often presenting a base for further custom spiral bevel gear generating services and allowing for perfect meshing of the custom gears.

Small module precision gears:

Precision gears of small modules are in demand in medical treatment apparatus and the aerospace field, where high precision and surface quality are demanded. Gear Generating can machine gears with a module as low as 0.5mm, achieving tooth profile accuracy of AGMA 12 or higher, and a surface roughness Ra≤0.4μm.

Figure 2: Helical gears have teeth that are inclined relative to the gear’s axis, forming a helical pattern.

When To Introduce Gear Grinding Services To Enhance Ultimate Performance?

Gear grinding services are an important finishing process in gear manufacturing. Although not required for all gears, in the following scenarios, introducing gear grinding services can significantly improve the ultimate performance of gears.

When extremely high tooth surface hardness is required: When the gears require carburizing and quenching to HRC 58-62, after heat treatment, the tooth surface will have deformed and become rough. Introducing gear grinding services can eliminate deformation, reduce roughness, and ensure gear precision and strength.

Ultra-precision application with AGMA grade 12 and above: Conventional gear grinding processes can control the precision at about AGMA grade 12. For even higher precision, gear grinding services need to be introduced for tooth profile and pitch error correction to improve the precision level to AGMA grade 13 or even higher.

In extreme environments: When gears are used in high-speed and heavy-load, low-noise conditions, gear grinding services for gears could alter the tooth surface topography to decrease impact and noise during meshing, enhancing wear resistance and load-carrying capacity, thereby ensuring stability in running.

Figure 3: Gear grinding is suitable for applications with extremely high requirements for tooth surface hardness, ultra precision grades, and extreme environments.

Feasible Solutions And Cost Optimization Of Small Batch Gear Manufacturing

In gear manufacturing, small-batch gear manufacturing (such as R&D samples, prototype making, spare parts procurement, etc.) often faces the problems of high costs and long lead times. Gear Generating technology is an ideal choice for small-batch gear manufacturing.

The most fundamental demands of small-batch gear manufacturing are cost reduction and shortening of lead times. In conventional gear forming, each gear tooth count calls for custom-made cutting tools, which means the costs are high, while the production cycle may drag on for 1-2 weeks with disproportionately high expenditure on tooling.

This technology eliminates the necessity of having dedicated cutting tools. It requires only programming and adjustment of parameters to process gears of similar modules but with different tooth counts, greatly reducing tooling costs.

In addition, the Gear Generating technology boasts high processing efficiency, allowing it to rapidly complete small-batch production.

Taking 10-50 helical gears with a module of 1.5mm as an example, from programming to finished products, it only takes 3-5 days, far faster than the traditional 7-10 days. Besides, JS Precision optimizes production scheduling to reduce waiting time and further shorten the delivery cycle.

How To Obtain Custom Spiral Bevel Gear Generating Services For Special Applications?

Custom spiral bevel gear generating services are designed for the machining of spiral bevel gears in special application scenarios, which require extremely high precision and meshing performance. To obtain this service, there are four rigorous steps that must be followed, in which the company JS Precision will provide professional support.

1.Requirements Analysis:

The application scenario of the customized spiral bevel gear will be discussed with you in detail, including: load, speed, installation space, operating temperature, etc. Those parameters are directly related to gear material selection and tooth profile design.

2.Collaborative Design:

Following an understanding of your requirements, JS Precision engineers will conduct a preliminary design based on the parameters and collaborate with you in tooth profile optimization, including recommending a structure according to load conditions and optimizing gear size based on installation space.

3.Precision Manufacturing:

After confirmation, we process the design into finished gears using advanced spiral bevel gear milling and grinding machines. A gear generating process would be employed to generate the tooth profile. We take stringent control of every processing step to ensure that precision is maintained-for example, the deviation in tooth pitch should not exceed ± 5μm during milling.

4.Testing and Verification:

After machining, the customized spiral bevel gear goes through comprehensive testing, which involves testing the accuracy of the tooth profile, detecting tooth direction errors, and testing meshing performance to assure perfect meshing of the mating gears.

If your special application requires custom spiral level gear generating services, please inform JS Precision of your specific requirements We will then arrange an experienced engineer to collaborate with you and provide you customized services in the whole process, starting from requirements analysis to testing and verification, ensuring you receive spiral bevel gears that meet your needs.

Case Study: 30% Efficiency Improvement The Birth Of A High-End Electromechanical Actuator Gearbox

Case Background

An aerospace company is currently developing a new generation fly-by-wire flight control system. The core electromechanical actuators need extremely high power density: continuous output torque ≥800Nm within a φ120mm diameter space, noise level below 70 dB, and a design life over 100,000 cycles.

These requirements cannot be satisfied by traditional gear machining processes, hence, the company approached JS Precision for assistance.

Challenges

- Limitation of Space: Center distance is limited by a three-stage helical gear transmission, the gear module should be precisely designed within 1.5mm. For this, traditional machining methods cannot guarantee tooth profile accuracy.

- Stringent Performance Requirements: Tooth surfaces must be carburized and quenched to HRC 58-62, heat treatment deformation must be controlled within micrometers, otherwise meshing will be affected.

- Noise Control: Gear dynamic balance and tooth profile accuracy are very important for noise suppression at high speeds (e.g., input velocity 6000rpm).

JS Precision Solution

1.Precision Generation: Gear generating uses a combination of the CNC gear hobbing and shaving processes in the generation of the gear profile. In this way, the accuracy of a gear profile is stably controlled at AGMA 12.

2.Deformation Control: Using a proprietary heat treatment process chain, pre-treatment reduces material internal stress, followed by low-temperature tempering and aging treatment after quenching controls the gear common normal variation to ≤8μm.

3.Final Grinding: Gear grinding services used as the final machining process precisely reshape the gear surface, improving the accuracy of the gear to AGMA 13, with a surface roughness of Ra ≤ 0.4 μm.

Our Results

To visually demonstrate the results, the following is a comparison of key performance indicators:

| Performance Indicators | Common Normal Variation | JS Precision Results | Improvement Amount |

| Transmission Efficiency | - | 97% - Improvement from original solution | 30% |

| Noise Level | ≤70 dB | 65 dB | Reduction of 5 dB |

| Cycles lifespan | ≥ 100 000 cycles | ≥ 200 000 cycles | Improvement of 100% |

| Gear Surface Roughness | - | Ra≤0.4μm | - |

| Common Normal Variation | ≤10μm | ≤8μm | Reduction of 20% |

This gearbox drastically improves the efficiency of the transmission, thereby reducing energy consumption and heat generated by the system. The noise level is also better than the target, meeting low-noise requirements, and its lifespan is far beyond expectation. Now, this electromechanical actuator has passed acceptance and is in mass production.

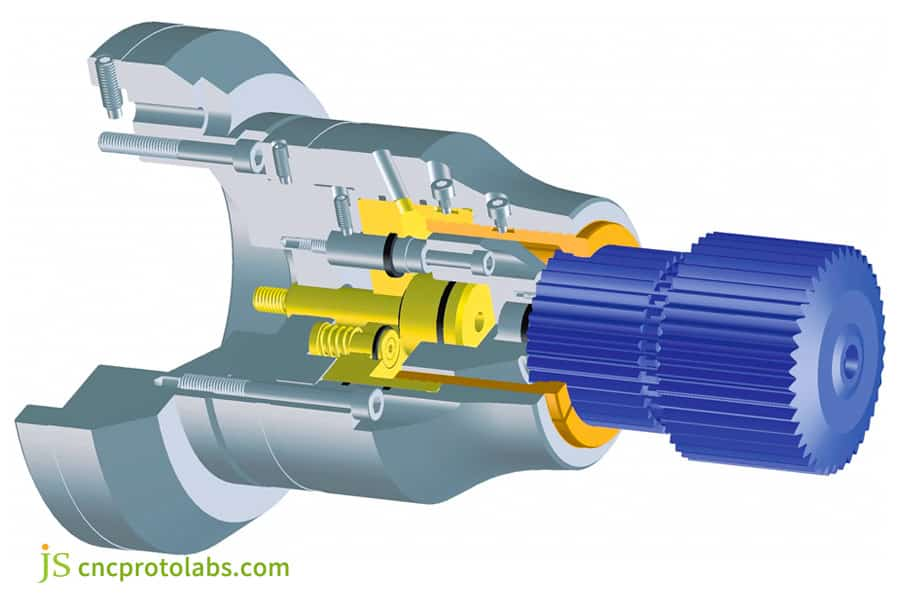

Figure 4: gearbox for electromechanical actuator

How To Partner With JS Precision To Obtain Your Ideal Gears?

Partnering with JS Precision for gear manufacturing and getting your perfect gears only requires four easy steps. We offer professional service at each step to ensure a smooth and efficient collaboration.

Step 1: Provide Your Requirements

You need to provide gear drawings that include data about tooth profile, module, number of teeth, precision grade, etc., application conditions about load, speed, operating temperature, and material requirements. For custom spiral bevel gears, the parameters of the mating gears and the dimensions of the mounting space also need to be provided.

Step 2: Technical Solution and Quotation

We will perform a technical analysis from your requirement and propose a technical solution, including the selection of gear generating process, the processing flow, and quality control measures. We will quote in US dollars according to the specification of the gear, quantity, and process complexity while listing all costs.

Step 3: Confirmation and Entry into the Precision Manufacturing Process

If the solution has been confirmed by quotation, we will immediately begin production scheduling and enter into the gear manufacturing process by signing a contract. The progress on the manufacture will be provided regularly, and an arrangement for a production process visit can be made.

Step 4: Enjoy Full Process Quality Tracking and Delivery Services

We will do a comprehensive inspection on every gear. After qualification, ship by the designated logistics and provide an inspection report. Technical support shall be offered in time once issues are found during use.

Whether you need standard gears or custom spiral bevel gear generating services, as long as you have gear manufacturing needs, immediately call JS Precision's service hotline, and we will arrange a professional team to connect with you from requirement communication to final delivery, providing you with full protection throughout the process and making it easy for you to obtain the ideal gear.

FAQs

Q1: What are the main advantages of gear generation technology?

The advantages of gear generation technology include high precision (up to AGMA level 12 or above), good tooth surface quality, and high production flexibility. Each tool can process a gear with the same module but different numbers of teeth, suitable for small- to medium-batch high-quality gear manufacturing.

Q2: Is gear generating the same as gear hobbing?

Gear hobbing is the most common and efficient method in gear generating, mainly referring to machining for external cylindrical gears and worm gears. Moreover, it is the most widely used high-precision machining method in gear machining.

Q3: When would you use gear forming-shaping or broaching?

Gear forming is applicable and more economical when internal gears or gear rings are machined, or for large batches of standard gears where precision requirements can be a bit lower. An example would be for the lower AGMA grades such as 10 and below.

Q4: Must gears always be ground?

No, but for those gears at high hardness after quenching, such as HRC 58-62, or gears requiring ultra-high precision of AGMA 10 and above, gear grinding services are one of the key processes to ensure the gears' final performance.

Q5: What is the minimum gear module you can process?

Precision gears as small as 0.5mm modules can be reliably processed by our equipment, it's designed for gears manufacturing in the medical device field or aerospace and will satisfy all the micro-transmission needs.

Q6: What is the design cycle for custom spiral bevel gears?

Generally, the design cycle of a customized spiral bevel gear will take 1-3 weeks, including requirements analysis, collaborative design, simulation analysis, and programming to ensure the feasibility of manufacturing.

Q7: Do you provide heat treatment?

The one-stop gear machining service we provide includes recommending dependable heat treatment vendors for you, outsourcing to the vendors, and full-process quality monitoring to make sure that the performance of the gear can meet the requirements after heat treatment.

Q8: What is the average delivery time from inquiry to delivery?

Delivery time from inquiry to delivery for standard gears is 2-4 weeks. In the case of complicated custom gears, such as spiral bevel gears, it can take much longer, up to 4-8 weeks depending upon the design and process complexity of gear manufacturing.

Summary

Gears are the heart of industry, and it is their precision that really defines critical function of a complete transmission system. For effective and accurate ways to engage in Gear Generating, and to create a reliable Gear Machining partner, look no further than JS Precision.

Be it for small-lot production of standard gears or for special application custom spiral bevel gear generating services-we've got you covered. Contact us immediately for free technical consultation and pricing to make your next project stand out with outstanding transmission.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com