From high-transmission protective eyeglass lenses that guard our eyes,to heat-resistant automotive engine parts,to drop-proof,transparent encasings of outdoor smart doorbells,polycarbonate(PC)has played a role in numerous things and industries over the last several hundred years.

It shares the pliability of plastic,yet,due to its carbonate groups,contains qualities much greater than those of most plastics like high strength and weathering resistance.People question:Is PC,with all its great performance,a technically plastic?

This article will give a full portrait of material PC,answering this question by its inherent nature,grade selection,performance advantages,processing mechanisms,and practical examples,showing its special value among the plastic family.

Key Answer Summary

| Comparative Aspect | PC(Polycarbonate) | PP(Polypropylene) | ABS(Acrylonitrile-Butadiene-Styrene) |

| Chemical Composition | Polymer with carbonate groups. | General-purpose plastic formed by propylene polymerization. | Terpolymer engineering plastic. |

| Central Properties | Excellent impact resistance,better transparency,satisfactory heat resistance. | Lightweight,satisfactory chemical resistance. | Satisfactory rigidity,easy mouldability,opaque. |

| Common Uses | Smart doorbell covers,vehicle lampshades. | Food packaging,domestic appliance internal parts. | Domestic appliance covers,vehicle interior components. |

| Formation Methods | Injection moulding,CNC machining,laser cutting,3D printing. | Injection moulding,extrusion. | Injection moulding,extrusion. |

| Material Placement | High-performance engineering plastic. | General-purpose plastic. | Medium-to-high-performance engineering plastic. |

| Answer Summary | Excellent comprehensive performance,best suited for upscale applications. | Excellent cost performance,best for general use. | Satisfactory workability and rigidity,multi-functional. |

Why Are You Able To Rely On This JS Guide For Your PC Project?

JS has specialized in PC material processing and application for decades and has gained vast and profound practical experience.

Authoritative qualification certification: Our quality management system has been certified according to international standards ISO 9001:2015 and IATF 16949 (for the automotive industry).

This means that we have a traceable and auditable standardized process for every step of the custom injection molding manufacturing process, from material PC incoming inspection to final injection molded part shipment, to ensure the stability and reliability of the output.

Technical patents and innovation: Our engineering team holds multiple patents related to precision mold design and special material PC processing technology.

For example, our rapid mold change system and unique cooling water channel optimization technology can significantly shorten the production cycle, thereby optimizing your injection molding price while ensuring quality.

Systematic knowledge management: We have systematically organized the process parameters, cutting data, and solutions for different materials of PC in previous projects, forming a huge process database.

When you consult through online injection molding services, what you are calling for is not the personal experience of a particular engineer, but the crystallization of systematic knowledge validated by the entire team.

This manual is not theory alone,it is a compilation of JS Team expertise in process design,material choice,and project assistance accumulated over years.Everything has been tested in the field,so this manual is an easy and trustable reference for your PC project.

JS is deeply rooted in the PC field, with practical experience in material PC selection, custom injection molding manufacturing, etc. The guide is the crystallization of experience. Choose us and enjoy professional services to help you efficiently land your PC projects.

Is PC A Part Of The Big Family Of Plastics?

To assign PC's category rightly,we first have to know the nature of plastics and then specifically study PC's distinct structure.

The Nature of Plastics

Plastics are primarily composed of polymers of high molecular weight.They can be formed at specific temperature and pressure and are capable of retaining their shape at room temperature.Their chain molecular structure endows them with properties such as plasticity and insulation,making many uses possible.

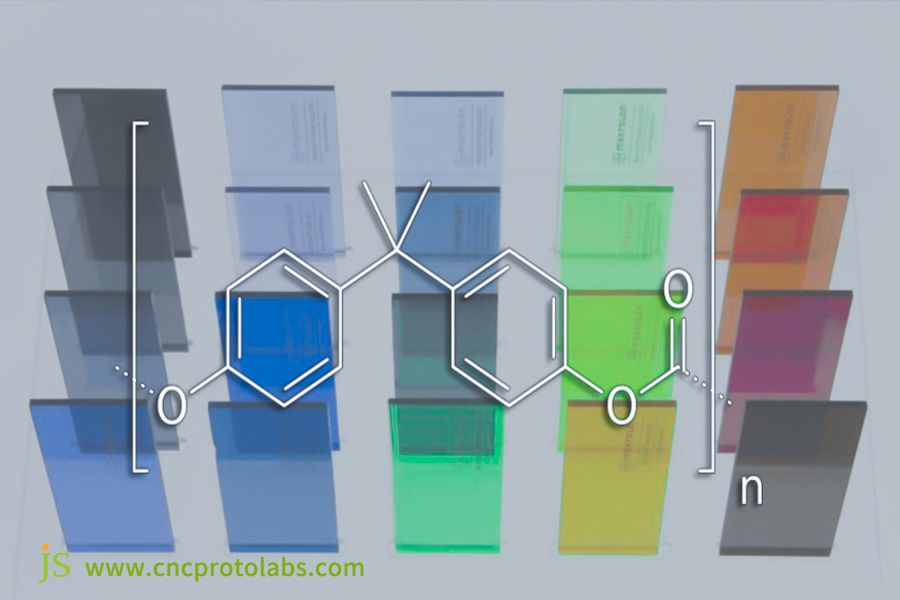

Special Structure of PC-Carbonate Groups

PC or polycarbonate is a plastic of high molecular weight and completely satisfies the definition of a plastic and belongs to the large family of plastics.Its heart and soul is its carbonate group(-O-CO-O-)within its molecule,which gives PC superb attributes like good strength,high transparency,and proper heat resistance,and therefore it stands tall in specialized application.

Since we have established PC's class,the question that follows is:how do we choose the appropriate PC grade for different applications?

We understand perfectly well the character of material PC and the benefits of carbonate groups,and can offer personalized PC solutions of high strength,high transparency,and other properties.In case you require PC application,select us and enjoy JS's precise production and processing ability for expert advice and smooth project execution.

How To Select The Correct PC Grade?

Different applications require different PC performance,and PC comes in different grades.The right grade maximizes performance and cost,particularly critical in custom injection molding manufacturing.

By Impact Strength

- Normal Impact Strength PC:Provides moderate impact strength and can be utilized in applications with low impact requirements,such as office equipment housings and inner components of domestic appliances,at an affordable price.

- High Impact Strength PC:PC altered to a great extent enhances impact strength and is used in safety-critical applications,e.g.,car bumpers and helmets,effectively protecting users.

By Heat Resistance

- Medium Heat Resistance PC:Offers heat resistance of 120°C-150°C,including day-to-day and general industrial use,e.g.,food contact containers and electronic component housings,and withstands deforming at higher temperatures.

- High-heat-resistant PC:Heat-resistant at over 150°C,some grades up to above 200°C.Employed in automobile engine peripheral components and LED heat sinks,and provides dependable performance even at higher temperatures.

Classification by Transparency

- Transparent PC:With more than 90%light transmission,it is virtually like glass but lighter and shock-resistant.Used in eyeglass lenses,cell phone screen protectors,and greenhouse skylights for light transmission as well as drop resistance.

- Translucent/Opaque PC:Masterbatches or modifiers are incorporated to reduce light transmittance.Used in appliance casings and automotive trim to meet a wide range of aesthetic requirements.

Choosing the right PC grade matters in production,and PC is used when high performance beyond regular plastics is needed.Let's discover the key to PC being more than plastic.

We help you choose the right PC grade by performance to cost–highly critical to custom injection molding manufacturing.Make PC part manufacturing smooth all the way from the source.Let us handle it to give you a solid foundation for further processing.".

Beyond Average:Why PC Isn't "Just" Plastic

In such crucial properties such as impact resistance,heat resistance,and transparency,PC gives enormous advantages over PP and ABS.Specific details are compared in the following table:

PC and PP(General-Purpose Plastics)Performance Comparison

| Indicators of Performance | PC(Polycarbonate) | PP(Polypropylene) | Application Scenarios |

| Impact Strength(kJ/m²) | 60-80 | 20-30 | PC: Children's toy shell |

| Heat Resistance Temperature(°C) | 120-135(Continuous Use) | 100-110(Continuous Use) | PC: Hot Pot Inner Shell |

| Transparency(%) | 90-92 | 40-60(Ordinary PP) | PC: Food Packaging Container |

| Density(g/cm³) | 1.20 | 0.90-0.91 | PP has advantages in lightweight demand scenarios. |

Performance Comparison of ABS(Engineering Plastics)and PC

| Performance Index | PC(Polycarbonate) | ABS(Acrylonitrile-Butadiene-Styrene) | PC application scenarios |

| Impact Strength(kJ/m²) | 60-80 | 25-40 | Outdoor electronic device casing. |

| Heat Resistance(°C) | 120-135°C(Continuous Use) | 80-100°C(Continuous Use) | Automotive engine compartment components. |

| Transparency(%) | 90-92 | Not transparent. | Car lampshade, instrument transparent panel. |

| Chemical Resistance | Stable to salt solutions,bases,and most acids. | Sensitive to a few organic solvents. | Chemical equipment parts. |

PC's excellent performance makes it one of the top competitors in high-end applications.However,processing PC pellets into end products involves a variety of different processes.

We possess vast experience of PC's supremacy over PP and ABS through its superior impact and heat resistance to make high-quality parts.Leveraging our long experience,we can make you improve your product performance.Join hands with us to deliver high-quality PC products to meet your requirement.

PC Materials Finishing:Various Processing Methods For Finishing PC Pellets

Various methods are employed to finish PC pellets into finished products,and among them,injection molding is the most prevalent.

Injection Molding

Injection molding involves heating and melting of PC pellets,injecting them into a mold,and afterward cooling them to form the final product.It is highly effective and can mass-produce high-tech products.

JS's engineering practice has shown that to obtain high-quality PC injection molding parts, the key lies in the precise coordination and control of melt temperature, injection speed, and mold temperature, which directly determines the magnitude of internal stress and the dimensional stability and optical performance of the final product.

Laser Cutting

Using a high-energy laser beam to cut PC sheets,it features high accuracy,smooth cutting,and zero mechanical stress.It can be used for processing high-precision,complex products such as decorative panels and electronic protective covers.

Power and speed have to be adjusted according to sheet thickness.The thicker the sheets,the higher power and slower speed.It requires no mold,and therefore it is suitable for small-batch,high-variety production.

CNC Machining

Machine tools controlled by the computer drill and mill PC sheets to high precision with good repeatability.It is suited for complex,high-precision products such as precision instrument casings and mechanical transmission components.The right tooling and parameters must be selected in order to avoid sticking of tools and surface roughness.High-precision hole and thread cutting can also be obtained.

3D Printing

Additive manufacturing technology builds PC material layer by layer without mold demand.It is used for R&D prototyping and small-volume customization.

Special PC filament or powder is required.The product performance and precision are enhanced,but the process speed is reduced and the strength is less than injection molded products.Currently,its application is growing in areas such as customized phone cases and glasses frames.

Now that we know about PC processing methods,let's put PC and glass against one another to understand which one is the"King of Drop Resistance."

We specialize in PC injection molding,CNC,3D printing,and other processes,and offer online injection molding services.Upload your design to receive a quote.With JS precision manufacturing,we can assist you in streamlining your PC parts production process efficiently.

PC vs.Glass:Which One Is Truly The"King Of Drop Resistance"?

Glass is clear and heat-resistant,but brittle.PC is clear and incredibly tough as well.The two are very different,though,when it comes to impact strength,density,and light transmission.The relative values are presented in the table below,clearly indicating which offers superior drop resistance:

| Performance Indicators | PC(Polycarbonate) | Glass | Advantages of PC |

| Impact Strength(kJ/m²) | 60-80 | About 1 | The anti drop performance far exceeds that of glass, and the risk of damage is extremely low. |

| Density(g/cm³) | 1.20 | 2.50 | More lightweight, which can reduce transportation, installation, and usage costs. |

| Light Transmittance(%) | 90-92 | 90-95 | The comparable light transmittance makes PC more suitable for scenarios such as children's rooms and sports venues. |

| Temperature Difference Resistance(°C) | Resists between-40°C and 120°C. | Easily shatters with extreme changes in temperature. | Good temperature resistance. |

| Weight(for the same volume) | Lighter | Heavier | It can reduce the burden on the supporting structure. |

In terms of impact strength, the impact strength of PC is 60-80 times that of glass. According to JS's drop ball impact test data, PC boards of the same thickness can maintain structural integrity even when subjected to impact energy far exceeding the glass limit, while glass is bound to break. Excellent drop resistance makes PC the preferred choice for high safety scenarios.

Clearly,PC is the undisputed "king of drop resistance" with advantages in terms of density and thermal resistance.It is also taking over for glass in applications such as building skylights and auto windows.

JS Real Case Study:Birth Of A Smart Home Device

Client Core Requirements

One client requested the development of an outdoor smart doorbell weatherproof enclosure,four requirements of which are key:

- High transparency and more than 90% light transmittance to ensure camera image quality.

- High impact resistance to withstand outdoor use and prevent device damage.

- Excellent weather resistance to be unscathed after exposure to long-term sunshine and rain without aging or cracking.

- Rapid prototyping to shorten the R&D cycle and capture market share.

JS Material and Process Solution

1.Material Selection:UV-Resistant PC Sheet

The selected UV-resistant PC material boasts light transmittance of 92%,meeting the camera requirements.Its 70kJ/m²impact strength withstands outdoor impact.With the addition of an anti-UV additive,it withstands temperature shifts from-40°C to 120°C,meeting weather resistance requirements.

2.Processing Technology:Customization in Phases

The initial prototype was produced with JS's high-precision CNC machining procedure in three days with±0.1mm accuracy control,and allowed for rapid design verification.

Small-batch production then utilized the hybrid of laser cutting and bending,avoiding the use of complex molds.Not only did this reduce the initial investment of custom injection molding manufacturing,it also lowered the production cycle to seven days.

Project Results

From design verification to small-batch shipping,the timeframe was shortened to just ten days,significantly shrinking the R&D and launch cycle to the market.Customer feedback also indicates that the housing continued to be high in transparency and strength following use outside for six months without evidence of aging or being destroyed.

Moreover,the initial cost advantage in injection molding prices will provide a cost advantage for future mass production,amply demonstrating the usability of the PC material and JS's technical proficiency.

As with our smart doorbell example,we use UV-resistant PC and flexible processes to solve your PC problems,from rapid prototyping to small production volume,shorter cycle time,and injection molding price reduction.Partner with us to make your project successful.

How Do You Start Your PC Parts Processing Project?

1.Define Your Needs

First,define the desired application of the PC component(e.g.,outer casing,electronics components),performance requirements(light transmission,impact resistance,etc.),production quantity(prototyping/small quantity/volume production),and delivery time to serve as the basis for material and process choices to follow.

2.Fill in Files to Obtain Quotes

Prepare design files in STEP and STL(securely and confidentially upload).Receive immediate tailored quotes,delivery cycles,and Design for Factoring(DFM)remarks via our instant quote system with a clear appreciation of injection molding price and other expenses.

3.Select Proper Services

We offer complete services:For rapid prototyping,we offer CNC machining and 3D printing,one working day production and tolerances of up to 0.005mm.For mass production,we offer injection molding(high-grade injection molding components production).We have over 100 materials(various PC types)and over 60 surface finishes.You can even track progress with our online injection molding services.

4.Begin Production

Once your plan is approved,production can begin.JS Precision Manufacturing and Processing has rigorous quality and time to ensure that your PC components arrive on schedule.

FAQs

Q1:Will PC material yellow after extended sun exposure?

Plain PC material will yellow with extended sun exposure.However,PC material with anti-UV additives resists UV degradation quite vigorously.For example,outdoor smart doorbell housings built with such materials can maintain high transparency after six months of outdoor exposure.

Q2:When making small lots of PC components,is CNC machining or 3D printing more suitable?

You get to decide.If you require high precision(within±0.1mm tolerance)and rapid checking of design,CNC machining is employed,which permits prototypes in three days.If the part is complex and doesn't require radical accuracy,3D printing doesn't require the employment of molds and is suitable for small-volume customization,but is slower and less durable than components CNC machined.

Q3:When injection molding one-off PC injection molding parts,will mold cost affect the overall injection molding price?

Yes.Mold expense is a significant initial cost in custom injection molding production.The larger the size of the part and the more complex the design,the more difficult and expensive the mold production is,which then raises the initial injection molding price.However as production lots become larger,the cost per unit of the mold decreases,leading to a lower total cost.

Q4:Why does my PC component border become white during laser cutting?

This is typically caused by thermal stress.Heat input can be reduced by optimizing laser cutting parameters such as power,speed,and air pressure.Skilled service providers are able to achieve almost crystal-clear cut edges through process control.

Summary

After reading this article,the question,"Is PC a type of plastic?"has been answered with a yes—PC not only belongs to the huge plastic family but also exhibits better performance.In short,PC is a performance plastic that carries a greater role in life and industry and enjoys rosy future prospects.

Whether you need a small batch trial production or bulk mass production,choose us and benefit from all-round support from requirement matching,solution tailoring,and production execution,ensuring that your PC components project goes smoothly.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com