When a factory faced a $40,000 investment in new machinery and two weeks of lost production since a master gear was damaged in a retired machine, engineers used 3D printing technology to address the crisis in three days at a cost of less than $400.

When an entrepreneur needed 500 individual product enclosures to test the market, standard mold-making costs totaled $20,000. However, online 3D printing services brought the cost down to $1,700.

This isn't magic,it's the real benefits of the 3D printing price revolution.This guide will show you: Custom 3d printing manufacturing doesn't have to be expensive and even small batches can be profitable!

Core Answer Summary

| Topic | Core content |

| 5 major cost saving scenarios | Rapid prototyping, small batch customization, integrated complex structures, on-demand spare parts, self-made tools |

| Strategies for each stage | Design (lightweight reduction of 30% -50%), prototype (online service saves 70%), production (mixed production), maintenance (digital spare parts library) |

| Cost control and | Technical selection, material management, batch optimization, post-processing optimization |

Are These Five 3D Printing Cost-saving Methods Reliable?

JS has considerable hands-on experience in 3D printing price reduction, with clients across various industries and demonstrating the viability of managing 3D printing price.

We leverage the inherent advantages of 3D printing, such as rapid prototyping and on-demand production, to help clients achieve significant cost savings in a range of situations.

For example,we have helped medical equipment customers reduce the development cost of surgical guide plate prototypes by 72% and shorten the delivery time from four weeks to five days through a custom 3D printing manufacturing solution. After optimizing the design for the drone company, the 3D printing price for its small-scale production has been reduced by 35%.

Whether it's controlling the high cost of mold for small-volume custom 3D printing parts for new business or streamlining the production process for complex parts for manufacturing customers, our team is able to truly translate technical solutions into tangible customer benefits, demonstrating the science behind 3D printing's cost-saving philosophy.

Our engineering team holds professional certification in additive manufacturing and, based on data analysis from over 500 successful projects, ensures that every cost proposal is validated through practice.

With years of expertise in saving you how much does 3D printing cost, the JS team provides you with fast, accurate quotes and custom 3d printing manufacturing solutions, with a wide range of material and surface finish options to choose from. We assure every investment to be worthwhile and your satisfaction as priority.

Is 3D Printing Truly More Expensive Than Conventional Manufacturing?

The myth of industry standard is that 3D printing is necessarily more expensive. The reality is about three variables: complexity of parts, scale of production, and customization requirements. It's not a one-size-fits-all model.

It's easy for folks to pose the question, 'how much does 3D printing cost?' but the response isn't static and is based upon case-by-case details.

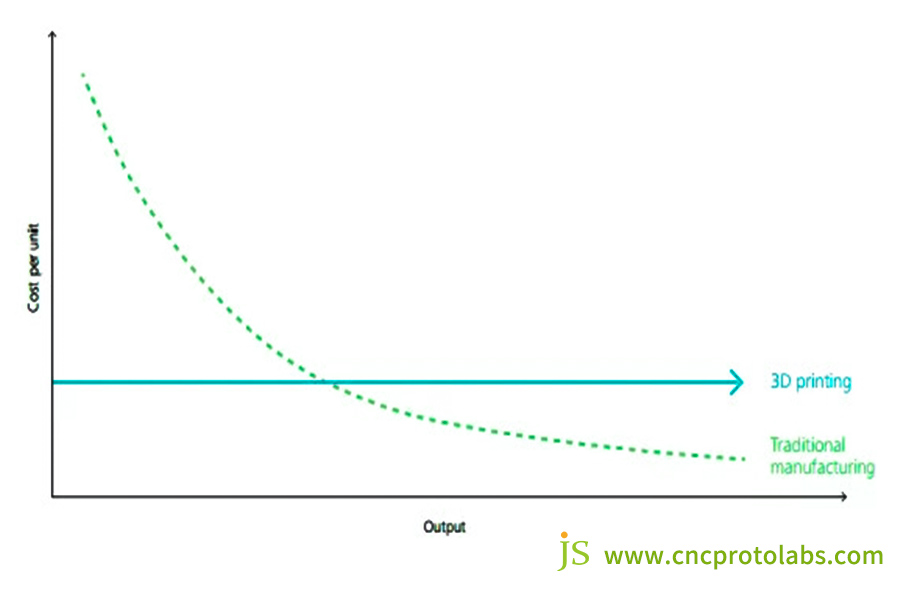

Scale of Production

In terms of scale of production, the variable costs are low and fixed costs high for the cost profile of traditional manufacturing (e.g., injection molding and die casting). For example, to create an injection mold set, it might cost tens of thousands of dollars. But with mass production (e.g., 10,000 or more parts), the cost per-part can be less than $1.

3D printing, however, has 'low fixed costs and moderate variable costs'. With the elimination of using molds, the part cost is between $5 and $100 and thus better suited for small batches of 100-1,000 units.

Part Complexity

As far as part complexity is concerned, traditional manufacturing has very little ability to handle complex structures.

For 3D printing parts with built-in flow channels or empty shapes, traditional processes involve a number of parts having to be taken out and reinstalled, which increases material and labor costs and reliability decreases.

Customization Requirements

When it comes to customization requirements, traditional manufacturing entails incredibly high 'customization costs'. Any adjustments to design could equate to re-molding. 3D printing only requires modification of the digital model, with virtually no additional cost.

Below is a multidimensional comparison of traditional manufacturing and 3D printing costs:

| Comparison Axes | Traditional Manufacturing (use injection molding as an example) | 3D Printing (use Multi Jet Fusion as an example) |

| Cost Structure | High Fixed Cost (Molding) + Low Variable Cost | Low Fixed Cost (No Mold) + Medium Variable Cost |

| Unit Cost | <$1 (Mass Production of 10,000+ pieces) | $5-100 (Small Batch) |

| Optimal Batch | 10,000+ pieces | 100-1,000 pieces |

| Complicated Structure Processing | Involves disassembly and assembly, with high cost and low reliability | Integrated molding reduces parts and assembly costs |

| Customization Cost | High (may involve re-molding) | Low (only includes modification of the digital model) |

In short, 3D printing has tremendous advantages in small-batch, complicated structure, and customized manufacturing situations, and therefore it is a core focus of innovation for the manufacturing industry.

Dispelling 3D printing cost myths. JS accurately diagnoses your requirements and provides competitive custom quotes within minutes. State-of-the-art technology and extensive material choice allow you to take advantage of the cost benefits of 3D printing.

Five Basic Cost-Saving Situations: End-to-End Cost Savings From Spare Parts To Large-Scale Production

The cost advantages of 3D printing extend end-to-end through the product life cycle, from design to large-scale production, and from spare parts to repair. The cost savings are particularly glaring in five basic situations.

Rapid Prototyping and Design Revision – Reducing Trial-and-Error Costs

The disadvantage of traditional prototyping is that with every iteration, costs mount. With CNC machining, making a metal prototype costs $200 one-time, and changing any design requires an additional $200 to re-machine. Any revision takes 3-5 days.

3D printing shatters this model. Designers can change a CAD model on a computer and print out a new prototype in hours with virtually zero revisions cost. For instance, with FDM technology, the material price of a plastic prototype is merely $5-50. With 10 shots, the total cost is significantly less than having one try in traditional methods.

The model shortens product development cycles by 50%-70% and total prototyping cost by 60%-90% across the board. For start-ups, it means being able to test more and get to market earlier in a single funding cycle.

Small Batch Custom Production - Avoiding Paying for Inventory

The minimum order quantity (MOQ) in customary production is usually a bottle-neck to small and medium enterprises.

For instance, in injection molding, the usual order placed to suppliers is at least 1,000 units to allow mold cost. But most businesses will only require 50-200 pieces, so they are buying too much and tying up money and exposing themselves to inventory risk.

The 'mold-free feature' of 3D printing perfectly solves this problem.Whether 50 or 500 units are being produced, manufacturing can be scaled to true demand, and unit cost does not rise much because batches are smaller.

The majority of the examples indicate that with 3D printing compared to traditional injection molding, cost is significantly slashed, and wait time for a mold is significantly lowered.

3D printing also eliminates old inventory. It was estimated by one industrial machine business that nearly 30% of the parts in its stock of spare parts were unpopular models that had fewer than once-a-year usage, and therefore inventory was costly.

When it transitioned to on-demand production with 3D printing, stock of these parts was reduced by 90%.

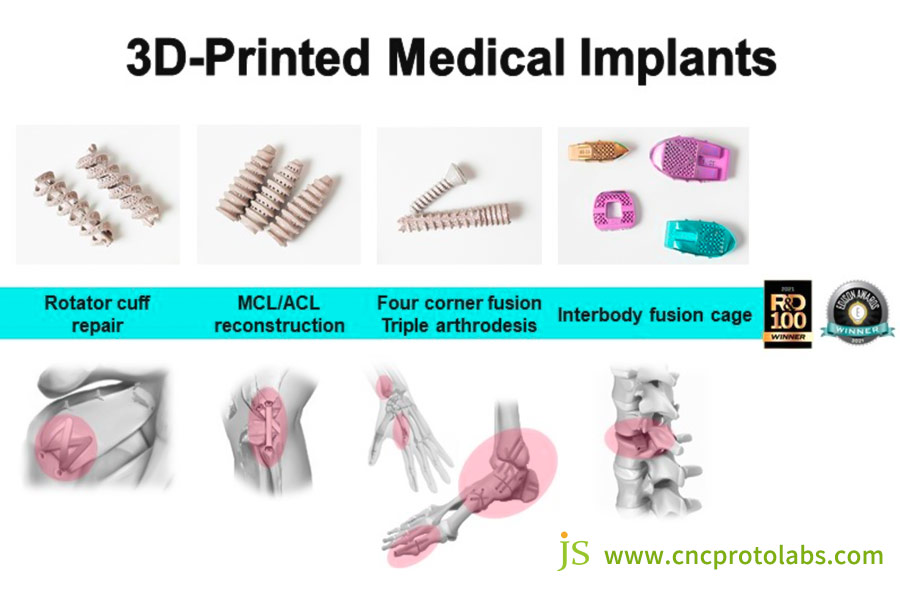

3D Printing Intricate Structures - Reducing Parts and Assembly Costs

In traditional production, complex parts generally generate 'split production + assembly', with threefold costs: the raw material cost of individual parts, the labor cost of assembly, and quality losses due to assembly errors.

3D printing's 'all-in-one molding' can circumvent these costs. In medical implants, for example, artificial joints consist of the incorporation of numerous components like the femoral head, stem, and spacer. Aside from being time- and labor-consuming, it also results in loosening due to gaps.

3D printing can print the whole structure directly, decreasing parts by 70%, cutting assembly costs by 80%, and increasing product life by 30% as there are no joints.

On-demand Spare Part Manufacturing - Minimizing Downtime Losses

Equipment downtime to wait for spare parts is a silent killer in manufacturing.

The 'localized, just-in-time' manufacturing capability of 3D printing has turned the spare parts supply paradigm on its head. Companies can store 3D-spares models in the cloud and, upon demand, have them printed directly on the factory floor or locally at a 3D printing center, enabling replacement within hours.

For manufacturers, this means: spare part inventories can be reduced by 80%, downtime cut by 90%, and indirect cost savings several orders of magnitude greater than the cost of the spare parts themselves.

Factory Production Tools – Reducing the Cost of Externally Sourced

Parts Jigs, gauges, covers, and other factory support tools are small but a cost control blind spot. In the past, these tools have been custom designed by external vendors, and this incurs a high premium (a 300%-500% markup) and has long lead times (typically 2-4 weeks).

3D printing allows companies to produce these tools in-house. The assembly jigs printed with 3D technology cost much less than bought-out jigs, and the design lead time to application is significantly shortened.

More importantly, employees could easily modify the design at any time based on actual requirements, making tools more flexible to production conditions and exerting an indirect influence on enhancing production efficiency.

From spare parts to mass production, from cost-reducing situations in the entire supply chain, JS offers precise printing capability and prompt delivery to meet your needs for rapid prototyping, small batch manufacturing, and so on. There are different choices of applications for different conditions so that larger cost savings are available.

Cost Control Strategies For Each Phase Of The Project

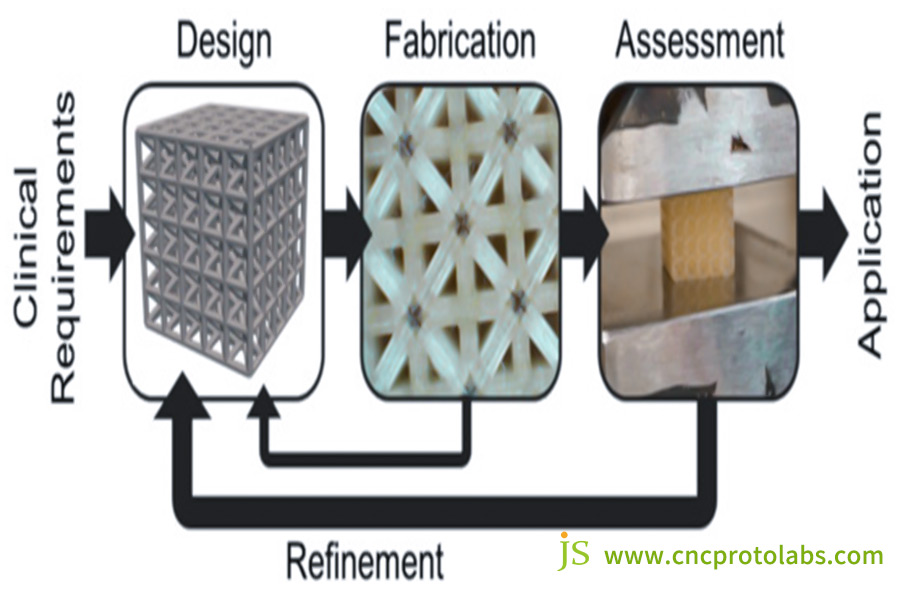

Design Stage: Reduce 'Hidden Costs' at Source

- Light Weight Design: Use honeycomb and lattice structures to reduce material use by 30%-50% and reduce cost.

- Reduce Support Structures: Reducing part placement angles will reduce use of supports by 60%, reducing material cost and post-processing time.

- Standard Interfaces: Differentiate customized and common components using traditional methods for common components to save cost and customization.

Prototype Stage: Reduce Trial and Error Costs with the 'Light Asset Model'

- Select the right technology: Use FDM for proof of concept and SLS for functionality testing to avoid wasteful expenses.

- Utilize online 3D printing services: Small and medium enterprises pay per unit, negating equipment depreciation and maintenance, and upfront investment.

- Several rounds of testings, small batch: Print a few units for the initial round of testing to avoid wastage because of design modifications.

Production Phase: Aligning Technology Economics and Scale

- Hybrid production strategy: Use 3D printing for short runs and traditional processes for long runs, balancing flexibility and mass production economics.

- Material pairing scenarios: Select materials by part function to avoid paying for redundant performance.

- Batch production: Bundle small parts printed within the same batch to maximize equipment use and reduce unit cost by 20%-30%.

Maintenance phase: Establish a 'digital spare parts library'

- Storing 3D models instead of physical parts: Reduce inventory costs. For example, one machinery factory reduced its warehouse space by 90%, saving rent.

- Localized production: Collaborate with regional service points to ensure rapid spare parts delivery and minimize downtime losses.

| Phase of Project | Cost Control Strategy | Result |

| Design | Light weighting/Thin Supports | Save 30%-50% Costs |

| Prototyping | Online Services | Save 70% of Investment |

| Production | Hybrid Production | Balance flexibility and mass production |

JS provides end-to-end support for cost control in every phase of the project from design through servicing, tailored to your strategy. Cutting-edge technology and streamlined operations help you manage every single penny to the exact cent.

Real Case Study: Robotics Startup-High Mold Costs Stifle Innovation

Client Background and Key Pain Points:

An eight-member smart home startup was creating a control panel with environmental sensors and needed 50 custom sensor housings for market testing. The housings had complex structure.

Traditional injection molding gave a total cost estimate of $15,000 with an 8-week lead time, outside their budget and jeopardizing the window. Redesigns were also costly.

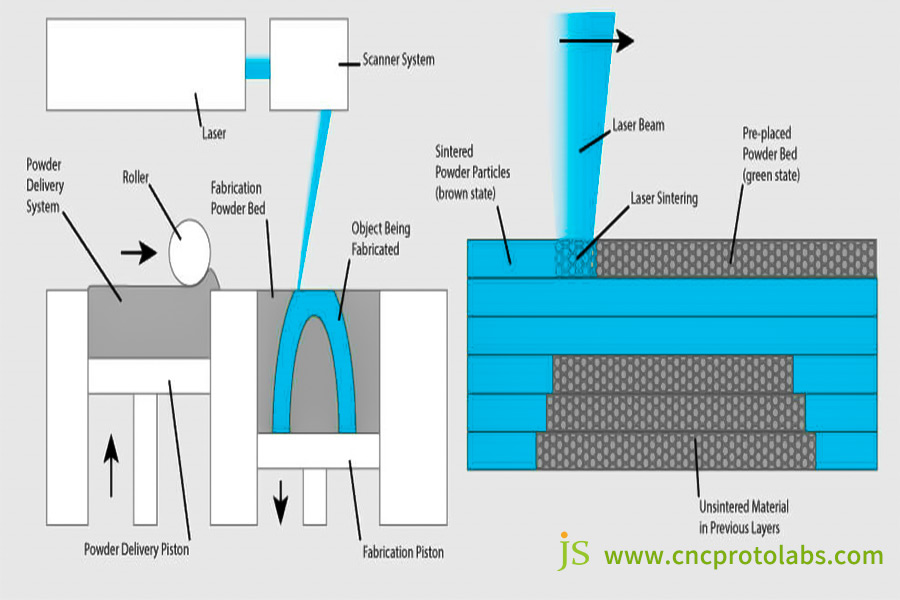

JS's Solution:

Innovative Utilization of Web-Based 3D Printing Service The JS team proposed Selective Laser Sintering (SLS) with Nylon 12. SLS allows printing directly in intricate structures, and the material is sensor-friendly. The online service cost totaled $3,000 with a lead time of 7 days.

Final Outcomes:

Finally, cost was reduced by 80% and cycle time was minimized by 89%. The company conducted early testing, rapidly improved its products, and financed against test results, capturing a prime market opportunity.

Just as we helped startups solve problems in previous cases, JS is dedicated to responding quickly to your 3D printing needs, efficiently handling small and medium-scale customized production, and offering rapid delivery to help you seize market opportunities.

How To Appropriately Manage Your 3D Printing Costs?

Cost management for 3D printing requires extremely careful planning, and optimization is achievable in each process.

Technology selection

In terms of technology selection, FDM (US$5-50) is appropriate for simple plastic parts but SLS (US$10-100) is recommended for complex parts. DMLS (US$50-500) is recommended for low and medium-volume metal production but binder jetting (reducing the cost by 30%) is thought of for high-volume production.

Material management

Material management-wise, the recovery rate of SLS powder is approximately 80%, which is a definite advantage in mass production. It is 10%-20% less expensive and superior in quality to purchase materials from the original manufacturer than from distributors.

Storage condition of the material should be managed carefully in such a way as not to incur the material loss of 20%-30% because of poor storage.

Batch optimization

Batch optimization includes determination of the critical mass. For example, when printing nylon parts using SLS, the part cost per piece is $50 for 50 pieces, at optimal cost-effectiveness. At lower cost-effectiveness rates, costs scale down at a diminished rate for above-100 pieces.

Post-processing

The post-processing adds 20%-40% to total costs. Reserve margins for polishing during design. Batch coloring expenses may be halved with automated machinery. Parts that are complex may be disassembled and reassembled once printed.

Accurately manage 3D printing expenses. JS is your right-hand man, making every step from technology selection to material management easier. Our rock-bottom prices and lean processes keep projects on budget.

FAQs

Q1: I only need a few parts, is online 3D printing services more cost-effective than purchasing a machine?

Typically, yes. Purchasing a machine yourself not only involves equipment purchase costs, but also maintenance, consumables, and so on. Outsourcing services, on the other hand, require less up-front capital expenditure.

Q2: How do I get a fast quote for 3D printing my parts?

Log in to the JS platform, upload the CAD of the part, select the appropriate material and process, and the platform automatically generates a report with the 3D printing price.So it is easy to inquire about quotes in an efficient manner.

Q3: Metal printing is more expensive than plastic. Why? What are the major reasons?

Metal printing is more expensive than plastic primarily due to large cost differences. First, the initial equipment cost is large. Second, they require protective consumables. Third, post-processing is complex with multiple processes.

Summary

3D printing is economical throughout the entire production line by eliminating physical steps, increasing design freedom, and maximizing resource utilization. It facilitates and extends traditional manufacturing and is applicable to leading-edge businesses, small-series production, and production of intricate structures.

Businesses need to consider 'how to best utilize 3D printing' and find the right cost vs. efficiency balance based on their size, nature of product, and production needs and make it a driver for cost reduction and efficiency improvement.

JS provides online 3D printing services with cutting-edge technology and innovative solutions to meet your rapid prototyping and customized production needs,. Regardless of project size, we promise satisfactory service and are your reliable partner on the path to cost savings and efficiency improvement.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com